There has been a near-mutiny of BBS02 owners (rioting in the streets) who have been disgruntled that their BBS02 units have shipped either without any grease in the secondary reduction gears or with the ill-suited white lithium grease in the secondary reduction gears. Both setups are not appropriate and will cause premature secondary pinion destruction and wear as well as making your drive unit much louder than it should be. A properly greased BBS02 running at full tilt should sound as loud as a large handheld drill and no louder.

“What did you say?”

*yelling* – “I SAID YOUR BBS02 SHOULD NOT BE THIS LOUD…”

![IMG_20151222_083756990[1]](https://electricbike-blog.com/wp-content/uploads/2015/12/img_20151222_0837569901-e1450811781638.jpg?w=700&h=498)

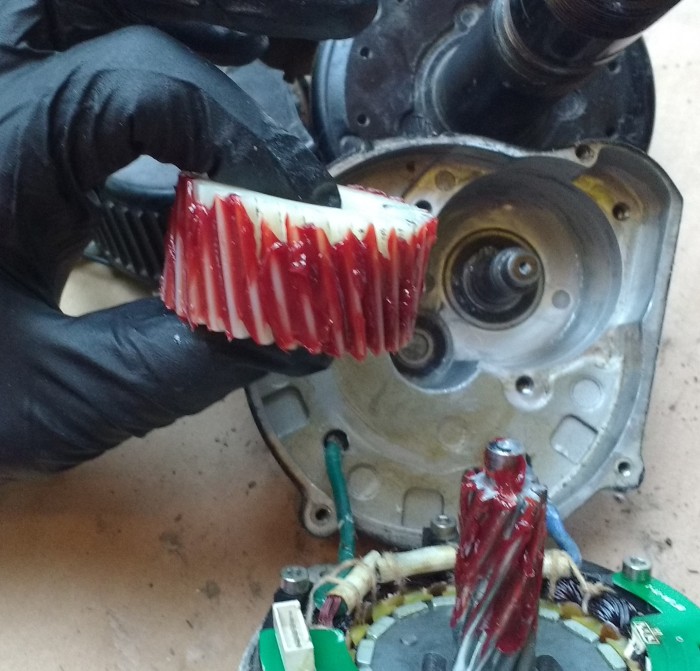

Strawberry, Vanilla or Chocolate. The white lithium grease is not viscous enough and the black moly grease degrades the nylon gear. The Goldilocks Mobilgrease 28 is just right. Yes, I actually eat off that table. Gross.

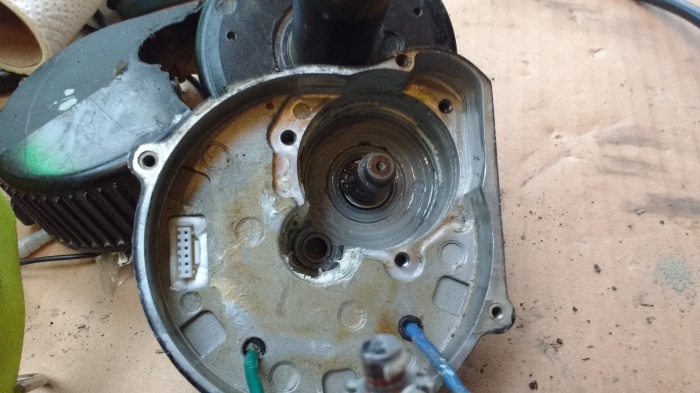

- The secondary gear reduction is located under the plastic cover on the BBS02 and is very easy to get to. Most BBS02 units have a thick black axle grease on these gears except for a few hundred units in mid-2015 that have shipped with no grease or with white lithium grease. Bafang has started using black axle grease on this reduction stage from here on out. The BBSHD has always had black grease on the secondary reduction gear as far as I know.

- The primary gear reduction you have to remove the motor to get at and uses a large white nylon gear. Bafang has always used white lithium grease on this gear and has never shipped drive units without grease here. There is problems with the lighter lithium grease spinning off the gears or hardening up when it gets several years old.

A few weeks ago I concluded that my nylon gear failure was probably caused by the black axle grease leaking through the bearing from the secondary reduction into the primary reduction. Because I felt that this was unacceptable I started shopping for other grease options that I could use to replace the black axle grease that Bafang was using and install it in both reduction areas. The Mobilgrease 28 I settled on is specifically designed for aircraft parts and is nylon gear safe and sells for about a buck an oz (available here) and is cherry flavored to boot (yum).

I recommend using heavy-duty black Nitrile gloves when working with grease of any kind, you can buy a box of 100 gloves from Walmart or Lowes for about $10. Get the extra thick black ones and not the crappy thin blue ones which are better suited for prostate exams. These greases are toxic and many kinds of solvents can absorb into your blood stream directly through your skin. Wanna know how I got so stupid? Washing my hands with Tetraethyllead to keep my 1961 Dodge Phoenix on the road for 8 years as a daily driver. Dumbest thing I ever did, except that one time I ran away from home to join the circus. They said I wasn’t tall enough to be The Giant and so I ended up working as the world’s most pathetic clown riding around on a children’s tricycle and setting people’s pants on fire. Living the dream baby. (not a true story)

![IMG_20151222_084120379[1]](https://electricbike-blog.com/wp-content/uploads/2015/12/img_20151222_0841203791.jpg?w=700&h=394)

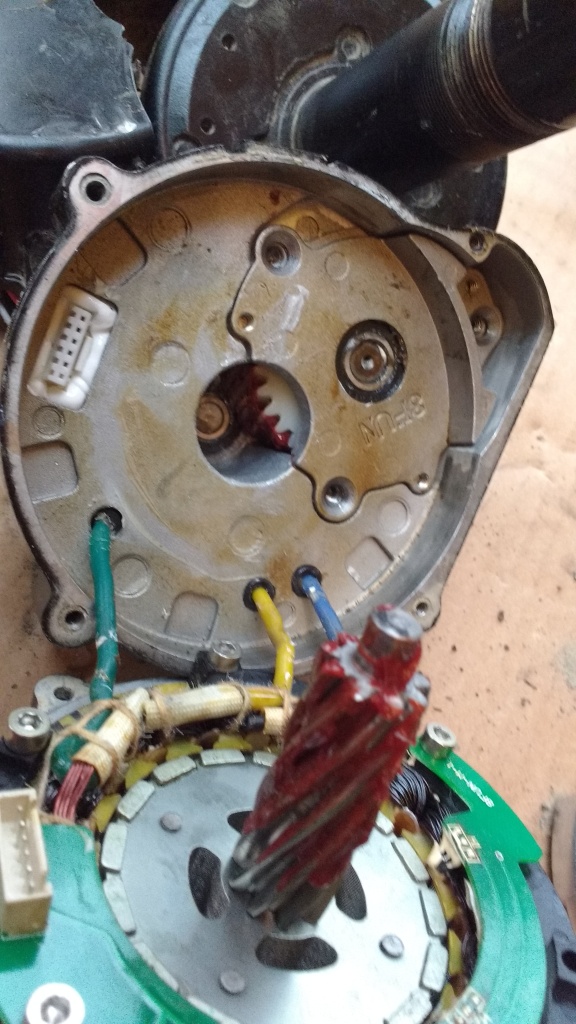

This is what your secondary reduction gears should look like, packed with grease from the factory. If it doesn’t then you need to take action. The pinion gear is the small gear in the top left.

If you’re hardcore like I am and want to replace ALL the grease in your BBS02 with Mobilgrease 28 then you will need to follow the steps below. The entire process takes about 30 minutes.

- Remove plastic cover as above and wipe off the black grease so it doesn’t get everywhere

- Pull the controller off with 2 hex screws. Make sure you use the right wrench and it’s fully engaged. Bafang puts these screws in WAY TOO TIGHT and you can strip them, I have.

- Remove the silicone around the 3 large phase wires where it goes into the case, remove the large white plug that also goes into the case and is encased in silicone.

- Unscrew the motor opposite the controller with 4 hex screws. As above these are put in way too damn tight.

- Carefully wiggle the motor back and the 3 phase wires on the controller side will slowly pull through.

- Remove the rubber triangle plug-in the top corner and then remove the triangle cover for the nylon gear.

- These 3 Philips screws are a bitch to get out. You need to brace the case hard and then use the right sized Philips screwdriver pushing down with all your might and then turning the screwdriver with a pair of vise grips. It’s insane to tighten Philips screws this tight, they are extremely hard to remove. Don’t give up.

- Remove the cover plate and then use lockring pliers to remove the lockring on the nylon gear. You might have to clean the white lithium grease off the top of the nylon gear.

- Clean the entire compartment of any white grease. It may start to be greyish from the black grease leaking through the bearing, it is on most drive units I have disassembled.

- Put Moblegrease 28 in the teeth of the nylon gear and the motor teeth. This is the best place for this grease to be.

- Remount the cover plate, motor and the controller. Do not over-tighten any of the screws, just make them sorta tight not Chinese prison laborer tight. When putting the motor back together carefully pull the phase wires in as the motor closes back together. You might want to re-silicone the controller connectors to make them watertight again.

- Use the Bafang axle removal tool to remove the 2 locking nuts on the opposite side of the axle as the secondary reduction gear.

- Pull the axle out about an inch. Do not remove the axle grease from the axle, there is no way for it to migrate into the primary reduction gear. Clean the grease off both sides of the large reduction wheel with a rag and you’re son’s toothbrush. Don’t tell him what you’re doing, just put his toothbrush back in the holder when you’re done and see if he notices. (That joke never gets old)

- Replace Mobilgrease 28 in the teeth of the large secondary reduction gear and push it in around the pinion gear.

- Push the axle back in, put the first locknut on so it is a little tight then put on the rubber washer then put on the 2nd locknut and tighten that down really tight. Test the friction of the bearings by turning the axle when you are done. The axle should not be loose (wiggle back and forth) and should not be so tight that you can’t turn it with your fingers both ways.

- Put the plastic cover back on. Don’t screw it back on with anything other than a handheld screwdriver. If you use a cordless drill you will probably crack the cover.

- That’s it, you’re done.

There is another article I did about replacing the nylon primary reduction gear on the BBS02 located here which also might be worth a look before you undertake this task. It has more descriptions that above and a lot more pictures as well.

Best way to coat the nylon gear with grease is to squeeze it into the teeth. Never use any black grease on this part. It breaks down the plastic and makes it soft, like the Stay Puft Marshmellow Man.

I used to use black moly automotive axle grease on the secondary reduction gear of my 8 BBS02’s and honestly it works great, but it can seriously deteriorate plastic parts over time. All my tubes of grease are designed to be fitted into a gun and shot out into grease fittings, but you can also just stick your finger into the end of the tube and scoop some out. Try to resist the urge to taste it. When your finger no longer reaches just use a mat knife to cut the whole cardboard tube down a little shorter so your finger will reach.

My feeling is that the white lithium grease that Bafang uses on the primary reduction gear is not viscous enough and tends to easily get flung off the nylon gear at the thousands of RPMs that the primary reduction gear runs at. The Mobilgrease 28 is a far more elegant solution as it has some clay mixed in to thicken the grease and to keep it sticking to the gears even when they are spinning around very fast. The white lithium grease that Bafang used to use on the older drive units seems to dry up and stop being gooey after a few years. My spellchecker doesn’t like the word gooey, but I do.

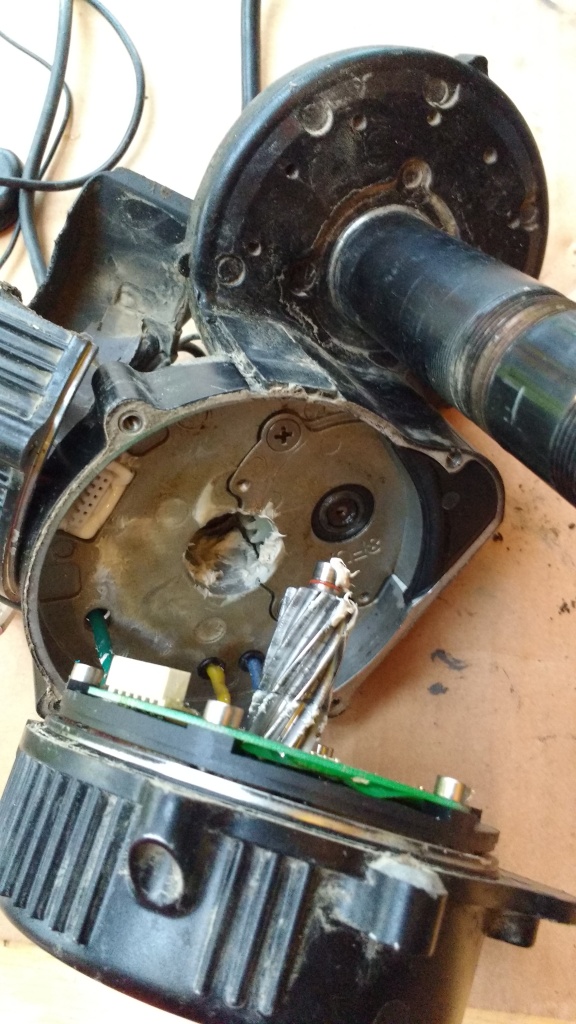

Cover plate replaced and motor about to be reinstalled. Don’t forget that rubber plug-in the top right-hand corner like I always do.

For some great videos from our favorite Aussie Speed-freak Bruno has done this video on the white lithium grease problems. Bruno used the black moly grease which I don’t recommend because it can leak through to the primary reduction gear. Volume control warning: You might want to check your computer speaker volume before you click on Bruno’s videos. You would be insane NOT to subscribe to his youtube channel as there are TONS of great videos on fixing the BBS02 and BBSHD and dude is funny. Not like Karl Gesslein of electric-fatbike funny, but actually funny, as in actually make you laugh funny.

This is the best way to grease the secondary gear in my opinion. Don’t clean the main axle. Nothing is going to work as well for the needle & thrust bearings than black moly grease.

30 minutes of proper maintenance on your BBS02 might be worth thousands of miles of uninterrupted service. Considering how much maintenance most people do on their cars, it is a small price to pay. If you find yourself in a place of shaming or blaming your BBS02 vendor, remember that they are not responsible for Bafang’s mistakes and shipping out hundreds of BBS02 drive units without grease on the secondary reduction gear is a serious blunder. If you must have the exact black moly grease that Bafang provides on the BBS02 then contact Eric at Lunacycle who has a tub of this very expensive stuff I’m sure he’d be happy to send you some if you bought your drive unit from him. Even if you didn’t buy your drive unit from him, Eric is a very nice guy and if you promise to give him all your ebike business till you die and sound really pathetic then he’ll probably just send you some. Bafang throws in a free Kentucky Fried Chicken bucket of black Moly grease with every $250,000 order.

If you have a BBSHD I do not recommend that you do this procedure at this time. If I find the black Moly grease seeping through to the Nylon reduction gear I will do a separate article for the BBSHD which is put together quite a bit differently. You should subscribe to this blog if you have a BBSHD and don’t want to miss the article.

Ride on.

Great article Karl, I might have to get a bbs02 just to change the grease, glad I found this site, waiting patiently for the luna build, my frame came today

LikeLike

Best grease, hands-down, is PlanetSafe AIM grease. I just purchased a CYC mid-drive motor and I am replacing the stock grease with AIM. It will reduce noise and heat. How do I know? I told Jon, founder of CYC, about AIM grease and they tested it and found it does just that. I just got 3 tubs of it shipped here to Canada from the US.

LikeLike

Hahahaha… I’m laughing here reading… you’re always delivering tons of good info in a very funny way… I always recommend your website to maaaany Bafang riders I reply in my YouTube channel… POWEEEER!!!

*I am getting a tube of this aviation grade grease and test here in different weather conditions in Australia, hopping this would be the solution for all that grease drama… =]

LikeLike

Hey Bruno did you try the aviation grease?

LikeLike

Did you try the Aviation grease?

LikeLike

Would Mobil 220 grease be alright to use as I have got to rebuild the gearing on my BBS02.as the 28 grease is hard to get where I live in UK

LikeLike

I have no idea, never used it. I’ve seen blue grease used in reduction gears like the cyclone but I have no idea if it will work with plastic gears. I can find nothing about it on the internet.

Karl

LikeLike

Hey Karl is it safe/recommended to use this red Mobilgrease 28 stuff with the Cyclone 3k as well? Thanks.

LikeLike

Mobil 28 is available here – & 1st class service from them as well

https://www.silmid.com/products/mob2800400-mobil-grease-28-390gm-cartridge-mil-prf.aspx

LikeLike

The full name is Mobil Mobilith SHC 220 Grease it is on Amazon UK. As well just wanted to say that your site is really good and has got excellent info on it. Big thanks from Uk

LikeLike

Karl you mention at the end of this article “If you have a BBSHD I do not recommend that you do this procedure at this time. ” Are you saying to hold off on both the primary and secondary areas for re greasing? My HD1000 is as quite as a mouse and I am temped to leave it alone until it starts making louder sounds but I do want to be proactive in looking after the motor with proper maintenance. ……….great article and thanks………….wayne

LikeLike

That is correct, until I see seep through problems with the grease into the primary reduction I do not advise it. The newer BBSHD has totally different sealed bearings than the BBS02. If I find problems I’ll update this article and post it on my FB page.

Karl

LikeLike

Hi man, so the mobilgrease is good for re-greasing the nylon gear from bbshd?

LikeLike

I have over 1000 miles and no issues so I would say yes.

Karl

LikeLike

I see, well I have only over 800km (2 months) by now. So, you are not recommending anyone to open the BBSHD for re-greasing until we hear something wrong. Mm, I will buy this mobilgreas28 for the time when I need it anyways. Thanks!

LikeLike

Pingback: 3 Months Of Singletrack Abuse On A BBSHD : This Masochistic Mid-Drive Still Begs For More | Electric-FatBike.com

Pingback: Plastic Gears Suck – Replacing The Nylon Primary Reduction Gear On the BBSHD | ElectricBike-Blog.com

That is correct, the grease on the BBSHD seems to be much better than the BBS02.

LikeLike

So, when we get a BBSHD, would you recommend to do nothing about grease at the start? Or, better to grease it anyway?

LikeLike

If it’s not noisy then don’t grease it.

LikeLike

Pingback: Bafang BBS02 and E-rad Hodrodding and Upgrade Parts | ELECTRICBIKE.COM

Thanks for a great site. I’ve basically learned everything I needed to do my first build from this site.

It’s been a while since this was posted and I was wondering if you, since then, have seen anything that indicates that the greasing of the bbs02 has been upgraded to the same standard as the bbshd?

Also, I seem to have quite some problems finding mobil 28 here in Sweden, can you recommend any alternative grease at all?

LikeLike

The BBS02 has been completely redesigned. I have one I’m testing and I’ll let you know if the new bearing has the same issue as the old one. I suspect so.

I have no idea what heavy grease will work well with Nylon gears other than Mobilgrease 28, sorry.

Karl

LikeLike

Ok, so I did some research and besides learning that my wife wasn’t amused over the disappearance of her toothbrush, I also learnt that a suitable, and in Europe quite easier to come by, alternative to Mobil 28 grease is Mobil Mobilith SHC 100 that is a PAO-base NG 2 grease with clay-thickener especially developed for electric motors. SHC 220 in the same series is also nylon-safe and is a bit cheeper. The difference between the two is mainly base oil viscosity. However, SHC 460 that looks really good on paper in terms of properties unfortunately contains moly so I would stay away from that option.

LikeLike

What is the update on this mobile grease 28? Whats the highest km so far without damage?

LikeLike

I recently re-packed my secondary reduction with Super Lube after reading about it on endless-sphere. Both times it quickly returned to sounding noisy while under power (pedal or motor). The second time literally lasted around 2 blocks before sounding noisy. I think Super Lube just isn’t viscous enough for this application. Has anyone else had this experience?

Is it possible that I’ve caused irreparable damage to my secondary reduction? If so, can anyone point me to where to find those gears so that I can replace them while re-greasing with Mobile 28?

Thanks

LikeLike

Yeah… I took apart my BBSHD to move the bottom bracket out to the right, so I could fit the Eclipse gear from Luna, and I read this article **NOT** thoroughly enough.

I thought– gee, grease sounds good. I took the thing apart and it cost me a few hours to reassemble.

First, the reduction gear is a part of the outer housing. So when you pull the cover off, the secondary (large) gear comes with it.

Here’s a hint– pull the cover off along WITH THE SHAFT. Push the shaft through while pulling the cover off, and be careful not to let the shaft slip from the cover or you’re in for a nasty treat.

There are 3 ratcheting tabs on a spring attached to the shaft. When you separate the shaft from the cover, the ratchet tabs pop out, and you’re going to spend hours trying to get the shaft seated properly while holding the three sprung tabs in at the same time. I tried a thin wire to hold the tabs– nope. Dental floss– wrong. I tried grease– stick the tabs closed long enough to seat the shaft– nada.

The fit is so tight, there’s no way to hold the three ratchet springs in while replacing the drive shaft.

The trick, it turns out– one of the tabs has a slightly larger guide. You have to pull the spring slightly over the tab so it holds itself in– then very carefully seat the shaft in the secondary gear. With a very slight wiggle (DO NOT FORCE) the shaft will pop into place and the tab will spring back into place.

Then hold the entire assembly together while you fit the shaft and cover back into the motor, careful to align the secondary reduction gear with the primary reduction gear (the small gear).

By now grease is just about everywhere– your fingers, your clothes, your hair– and you’ve got a massive cleanup.

The motor feels better with the added grease, but it’s not worth the effort and be prepared for a rough evening of messing around with the crankshaft.

LikeLike

It turns out the ratcheting 3 springed tabs are the clutch. I’ve found a video showing a much easier way to reassemble:

https://lunacycle.com/parts/bafang-parts/bbshd-parts/bbshd-clutch/

LikeLike

Rotate the crank on the non-drive side while inserting the freewheel clutch and all the teeth will snap in place. It’s easy.

LikeLike

Cant wait for your future BBSHD maintenence articles.

LikeLike

Mo,

I’ve been beating the panther piss out of every one of my 4 BBSHD’s and zero failures. Three of them I’m running at 60 amps through almost a foot of heavy wet snow every day. No issues. I just can’t believe the abuse this drive unit can take. Unreal.

LikeLike

Is there a good video on the easiest, most bang for the minute, way to regrease the BBSHD? One of mine is starting to be noisy. I assume I’ll use Mobil 28 on everything.

LikeLike

Any more word on how the bbs02 units are being lubed from the factory these days? I’m putting a new one in my wife’s bike and would like to know if I should regrease it with the Mobile product.

LikeLike

This is real noob question and almost embarrassed to ask it. I got my hands on a tube of the Mobil 28. to apply some to my BBS02 (and maybe another noisy geared motor I have. I didn’t give any thought to a grease gun. Do I need one to apply this stuff or do just use your finger or substitute?

LikeLike

Nah man grease guns are to big to get in between them teeth especially for the bbs02. Bbshd a lot easier to grease since its more open. For the bbs02 just use your fingers and you must push the grease down hopefully reaching all the way in or halfway if possible. Make sure to put tons on the small pinion gear cuz in reality thats your most metal on metal contact.

LikeLike

___123___Mobilgrease 28 & BBSHD/BBS02 : Because A Good Mid-drive Is Better Seen And Not Heard | ElectricBike-Blog.com___123___

LikeLike

Hi Guys, Thanks for all the great information! I’m the proud new owner of a BBSHD from Luna Cycles. I was all set to break into my new crankcase until I read this article. I was even considering installing a lube nipple and weep hole (threaded) so I could push out all the air and make yearly lube changes easy! I’m going to hold off on that and wait further word from the experts. Thanks!

(can pictures be posted with comments? I don’t see a way in to do that)

LikeLike

Not really. Sorry.

LikeLike

Pingback: Destroy Everything You Touch : Managing The Repairs On Your Ebike Fleet | ElectricBike-Blog.com

Are there any other recommended / alternative lubricants for the main axle, including the needle & thrust bearings, besides black moly grease? I have Lucas White Lithium Grease, Super Lube 97008 Silicone Lubricant, and a few others. If not, can anyone recommend a good black moly grease online? I see the Lubrimatic in the photo. I am in Hawaii and sometimes getting the right product can be challenging.

Thanks for the info. It has been immeasurably useful.

LikeLike

Pingback: Bafang Speed Pedalecs – iBikes.ro

So why on earth are these things made with nylon instead of metal in the first place?

LikeLike

Quieter

LikeLike

Any further thoughts on experiences with Mobile SHC 100 vs Mobile 28?

LikeLike

Mobilith SHC 100 will not only work perfectly, it is in fact superior to Mobil 28 (which is essentially obsolete, and that is why you folks are having trouble finding it outside the USA). Mobilith SHC 100 can be used for the entire motors grease, it performs extremely well throughout any of these motors, including the newer more advanced units like the Bafang Ultra etc.

LikeLike

Why not also list some other options for grease, as Mobilgrease 28 is not a readily available option to buy from a local store.

LikeLike

Pingback: Quit your whining : How much ebike motor noise is too much? | ELECTRICBIKE.COM

Pic on title “Cover plate replaced and motor about to be reinstalled. Don’t forget that rubber plug-in the top right-hand corner like I always do“

The coils are black! That’s no good at all, this engine was driven on high Amps at low RPM.

LikeLike

i use coocoonut oil

LikeLike

Works great as an organic sex lube too…

LikeLike

Hey Karl – to grease the worm drive do we need to dismantle the connectors – in the photo above it looks like you haven’t

LikeLike

woutdnt mobiltemp shc 100 be a better proposition as its clay added?

LikeLike

This is what I got after conferring with a guy in the UK who sells bbS02s and has had good results with it.

LikeLike

What an insightful and well-written article! It’s truly refreshing to come across a piece that not only showcases technical expertise but also emphasizes the importance of a smooth and silent riding experience. The way you’ve highlighted the benefits of Mobilgrease 28 and its impact on the performance of BBSHD/BBS02 mid-drive systems is commendable. Your approach of focusing on enhancing the overall biking experience by reducing noise and ensuring efficient functionality is a game-changer. Keep up the great work in shedding light on these essential aspects that contribute to a more enjoyable and satisfying ride. Your dedication to providing valuable insights is truly appreciated by fellow biking enthusiasts like myself!

LikeLike