I’m not sure why they made this primary reduction gear on the BBSHD out of plastic. People keep telling me that it makes the drive unit nice and quiet. If I wanted a quiet motor I’d put it under my pillow at night, or spring for a decent Sine wave controller. People say that it works like a fuse to make sure that if there is too much power going through the motor that it destroys the plastic gear instead of the expensive motor. To that I say hogwash, I ran 3250 Watts through the motor under extremely high load and the windings were just fine. The reason that Bafang uses a plastic gear as the primary reduction in the BBSHD is due to one thing and one thing only.

To save a few Yuan.

Don’t believe me? I’ve been to China and I can attest that one of the biggest complaints that the Chinese people have against their own Chinese products is that they are cheaply made. Don’t get me wrong, the BBSHD is the most reliable mid drive I’ve ever touched by a long shot. The weak point of both the BBS02 and the BBSHD is the nylon gear.

There are two things I’m super excited about with the BBSHD that are drastic improvements over the BBS02.

The first is the new white lithium grease they are using on the primary reduction system. The old lithium grease on the BBS02 was the consistency of whipped cream and it was quickly flung off the primary reduction gear which spins stupid fast, over 2000 RPM. The new grease is the consistency of extremely sticky toothpaste and it seems to stick to everything. Even after 3 months of hard riding on my BBSHD there was still grease in between the valleys of the gear teeth on the nylon gear and the motor shaft. Although these grease seems to collect on the bottom of the gear, there was plenty of it to be found on the gears itself.

The second improvement was that there was absolutely NO seepage of black moly grease from the secondary reduction system into the primary reduction system even after 4 months of hard abuse. This was a huge problem with the BBS02 and I believe it was the primary cause of Nylon gear failure on the BBS02.

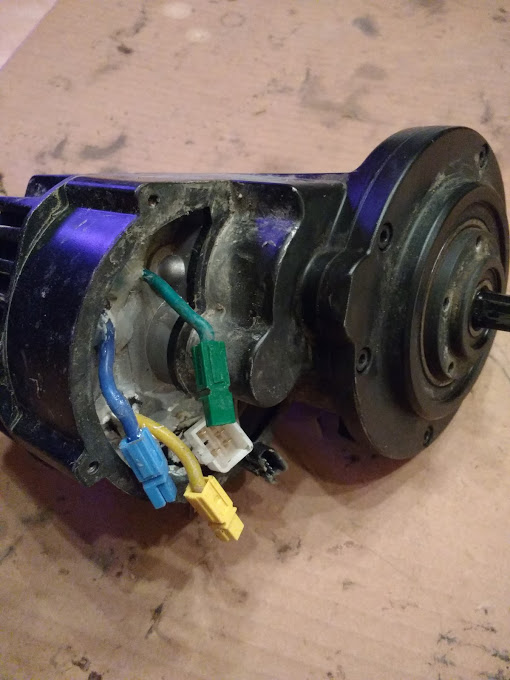

Replacing the Nylon gear on the BBS02 is much easier than replacing one on the BBSHD. The biggest difference is that the rotor tends to stick with the main drive case and the press fit bearing when to stator is removed. This means you have to overcome the pull of the magnets in order to remove the motor which is pretty hard to do without damaging anything.

- Remove the drive unit from the bike.

- Remove the controller and carefully remove the silicone around the 3 phase wires and the hall wire plug that goes into the case. Do not cut the wires or damage the insulation. This is incredibly easy to do and if you do damage the wire insulation then you will need to cover it with heat shrink tubing after you put the motor back together so the phase wires do not short against the case.

- Remove the 4 hex bolts on the motor side and carefully pry it apart. Pry both sides evenly. Once you get it started make sure that the cardboard gasket does not rip. Using the screw driver with the case open less than 1cm carefully go around the outside. It is important that you don’t rip this gasket and if you do that you replace it or seal the seam with silicone when you put it back together.

- Eventually you should be able to get the stator (motor case) apart which will probably leave the rotor attached to the BBSHD housing. If you grab the rotor with your hand and pull it really hard straight out you should get it to come out. If you have to lever it with screwdrivers then make sure to lever on both sides with equal pressure at the same time.

- Now you have access to the cover plate with the Phillips screws from hell. You will need to work hard to not strip these babies. Make sure to use the right size Philips head and then attach vicegrips to your screw driver. You will need to put the BBSHD on cardboard and lean on it with ALL YOUR WEIGHT and carefully turn the screws. If you’re lucky they will come out without stripping, if you’re not lucky then it’s EZ-out time. Removing stripped screws is a royal PITA, so my advice is don’t go there.

- Use 3 of the 4 small hex screws from the motor mounting to carefully screw into the empty holes next to the removed Phillips screw holes. This is a press fit bearing and you will NOT be able to get that plate out properly unless you carefully tighten each bolt in sequence until the top plate pops off.

- Remove the locking ring. This is more of a pain in the ass than you think it should be. If you have a decent pair of lockring plyers then it makes the job doable. If you don’t well good luck to you.

- Use a L shaped hex wrench to get under the nylon gear and pull it straight up. You’ll have to pull very hard. If your fingers slip on the wrench then use a pair of vicegrips to hold it and pull straight up.

- Clean out all the plastic debris and grease that you can in the hole. If you leave any plastic pieces in there it will mess up the next gear you use. I only say that because the first time I did this on a BBS02 that is exactly what I did. If I can do it then you can too.

- Grease the crap out of the gear with a heavy Lithium grease or Mobilgrease 28 which all I use. Do not use a black moly grease on this gear or it will weaken and fail.

- Replace the gear, put the lockring, replace the plate, tighten down the Phillips screws as hard as you can without stripping them.

- Carefully replace the rotor and the gasket. If the gasket ripped get a new one or seal the edges with silicone. Replace the stator then pull the phase wires back through the housing toward the controller. Check the insulation on the phase wires and put heat shrink tubing on it if it has ripped. Silicone the holes with the phase wires and plug-in the hall sensor plug to the motor and silicone around that as well and replace the controller.

You will need to carefully make sure that the gasket only sticks to one side before you pull it apart.

Replacing the Nylon gear takes about an hour or so for a BBSHD vet. It might take up to 2 hours for an amateur. You will know if the primary gear has failed if the motor turns but offers little or no resistance. When the nylon gear peanut butters, it also generally becomes extremely hard to roll the bike backwards. If you think it might be the pinion gear your can pull off the secondary cover and check that first before you rip the drive apart. That only takes 5 minutes and even if the pinion gear is fine you can grease it up with Black moly grease or Mobilgrease 28.

Although these steps seem pretty intimidating I can assure you that they are not that hard to do. You can get a replacement nylon gear stateside from Lunacycle.com for $20 here. I have bought these for the BBS02 from China and they were a few dollars cheaper but they cost a lot to ship and took forever to arrive. Be aware that the nylon gears for the BBS02 and the BBSHD are completely different and not interchangeable no matter how hard you push them on.

Ride On.

Isn’t it the case that a metal gear would require robust servicing from the end-user, and perhaps oil-based lubrication rather than sticky grease? If so, I can see why they’d not want to manufacture something that would need to be oil-tight too, like an automotive gearbox casing. Cheapness again?

LikeLike

I think the bigger problem is the grease tends to fling off the gears. Because the Primary spins so ridiculously fast the Nylon gear will generally work even if it has little or no grease on it. A composite gear would work better, steel would be heavy and over time would wear away at the rotor gear. 7075 Aluminum would probably be best.

LikeLike

Do you think an impact driver and a heavy hammer would work on the Phillips screws? Japanese bikes from the 60s and 70s used lots of soft Phillips screws on the cases and that was the preferred removal tool. Once they are out is there room to replace them with a hex headed screw so they can be torqued?

LikeLike

An electric impact driver allows you to put all the longitudinal force into the screw while the motor takes care of the rotational impacts. It’s great to do it once to get them out, and never use them again.

LikeLike

Sweet, thanks for the tip. I don’t own an impact driver.

LikeLike

I tried an impact screwdriver on a BBS02 and stripped a phillips head.

LikeLike

I’ve done 3 plastic gears (9 screws) using the full weight and vicegrips method without one stripped screw (knock on wood).

Karl

LikeLike

From Honda MC experience – get a JIS Japanese Industry Standard bit or screwdriver – Phillips are designed to cam out of the slots

LikeLike

Yes, it’s what I suggest using for removal.

LikeLike

I would not beat on my case with a hammer. Hex screws would be a better choice.

LikeLike

Maybe we could start a project with a good machine shop to make these plastic gears out of 7075 aluminum? What about the guy who works for Lunacycle that makes the amazing chain rings? It shouldn’t be that hard to copy them?

LikeLike

Kim said no. I’d pitch in if you can find someone.

LikeLike

I will check with a local company about copying the gear when I get back to Canada. I just realized – one big advantage of replacing the plastic gear with a metal one would be that you could use all the heavy black moly grease needed. Assuming the motor wasn’t pushed way past it’s design limits, reliability should be pretty good.

LikeLike

Go directly to a GEAR SPECIALTY shop, they are set up for making gears, so will be much cheaper and no guesswork.

also , does the factory bearing come out of the nylon to be used in a new gear ?

Just Google new gears made. I’ve used several of them on repairing a old boring mill in my machine shop.

LikeLike

Make a mold of the original gear using silicone from some place like smooth on. You could then pour some new parts using a stronger material, perhaps with some sort of fill. Nylon is a pretty tough material, but its still a thermal plastic and you could improve strength a lot using a thermal set plastic.

LikeLike

would need to get your hands on a 6 axis machining mill witch are vary expensive, or you could have it 3D printed in metal at some of the 3D printing places such as shape ways witch can do different types of metals.

LikeLike

I have an STL file of the BBSHD gear. Shapeways wants $140 plus shipping to print it out of steel. I just hired my print and it will be here in June. I am looking to see if there is any interest in running a beta test. Just email me at mikeebikeshawaii@gmail.com. Note: This is an untested method and may cause catastrophic failure to the BBSHD inrunner pinion gear which is about $60 to replace. I am looking for DIY’ers who run 2500 watts or more and are not afraid of the potential carnage.

LikeLike

Make sure you build the one-way roller clutch into the gear as well.

LikeLike

Did you wind up doing this? If so, how were the results?

LikeLike

If you made small gear out of metal, then it would last longer, but…it would also cause measurable wear on the large gear. The major benefit of the plastic gear is that the large gear should last decades, even if you have to replace the small one once a year due to heavy use.

It would have been “possible” to design the case do that the bottom third of the large gear passed through an oil-bath (like a car differential), but…that would be more expensive. Bafang has been very sensitive to pricing, and are keenly aware of how customers respond to component prices.

LikeLiked by 1 person

Composite then. Anything but Nylon.

LikeLiked by 1 person

Yeah, you’re right. Composite would be an improvement.

LikeLike

Wow Who would have thought this kit would be as unreliable as the BBs02 ? As you guys mentioned here their is probably a very good reason why the other high performance mid drive kits like the AFT 1680w have moved away from grease and onto oil bath lubrication. Most likely is top stop such issues as it provides the best lubrication and cooling of the gears which grease does not do as it doesn’t cool them or stay on them after long periods of usage. Also plastic for a gear material has no place on a high power high torque mid drive, as soon as it heats up it turns to butter and teeth brake as pictured . But yeah this is a product made cheap to sell and replace every year it seems….

LikeLike

Do you even read brah?

He abused it for a few months without failure, so hooked up an external controller with 65 amperes, destroyed his metal rear cassette sprocket instantly before having to load it up on a taller gear to burn the primary nylpn gear. \m/

LikeLiked by 1 person

Typically the nay sayers are non users. I don’t agree with Karl, but at least he lives is. I think the plastic is a savrificial design.

LikeLike

Hmmm, if you are going to redesign the plastic gear, why not do an American knockoff on a Chinese knockoff and just build the whole motor over here – the right way. Surely there is enough expertise on this continent to do it at a comparable price. It ain’t rocket science you know. And there is a potentially huge market….

LikeLike

I have a background in manufacturing as an engineer. It certainly could be done but not likely as cheap. Many American companies rely on automation to avoid high labor costs and automation has a high initial investment cost that the company would expect to spread across many units.

Its the reason manufacturing jobs won’t be coming back to the USA as quickly and plentifully as the political pundits would have us believe. Whatever does come back will be quite technical and fewer in number than the jobs that left. An assembly line with 25 workers is replaced with an automated line with two technicians keeping the line rolling. Perhaps one loading and unloading products or that could be replaced with a picker robot.

What I would like to see would be a replacement gear for the nylon gear easily purchased and/or replaced with a soft metal instead. Another angle would be a motor design where this gear is easily replaced without the removal of the motor from the bike. Something where you pop a cover and slide out the ruined gear and slide in the replacement.

An electronic soft start setting would prevent this (and maybe that already exists). I’m studying up to buy this motor for my bike soon so forgive my naivety.

LikeLike

Soft start can be programmed on the bbshd, you just need a programming cable and a PC with USB plus the software.

LikeLike

After reviewing all the comments and with some (not allot) of knowledge regarding these motors If that gear is not to hard to get out plastic might be the best way to go . Maybe glass filled nylon or something tougher. However aluminum should hold out 3 or so times longer. I do not think that would hard the larger

gears unless they are very soft which knowing the chinese is more than possible.

I run a plastic injection mold making shop and we do make gears with 4 axis equipement. However they

are not spiral gears. More views on the gear would be appreciated. I am on the fence with a BBSHD purchase and have the ability to customer machine or even mold a gear if needed. A 3d printed gear as

far as I know not hold up.

LikeLike

Get the BBSHD, I ran over twice the peak amps that the drive was sold with (65vs30). I’ve beaten on the BBSHD HARD for 4 months without failure.

3D printed gears will not work.

LikeLike

Pingback: Is It Wise To Power My 48 Volt Mid Drive System With A 52 Volt Battery, Master Yoda? | ElectricBike-Blog.com

Pingback: Lunacycle Releases Their 50Amp BBSHD That I’ve Been Testing For 6 Months (But You Gotta Buy The Whole Bike) | ElectricBike-Blog.com

Hey Karl, great collection of info and experience you have here. Do you think it might be worth looking at nipples? Not yours or anyone elses for that matter, but rather of the grease variety. Possibly one each could be located in the primary and secondary gear areas so the gears can be periodically greased without pulling the motor apart. I’ve done close to 1000ks on my BBSHD and although it doesn’t sound noticeably different I’m all for preventative and periodic maintenance.

LikeLike

I don’t think it’s necessary, although it’s not a bad idea.

LikeLike

How certain is it that I will need to replace this part on a BBS02 if I used it within it’s operational limits (i.e. PAS only, no extensive high speed assist)

LikeLike

Unless you are using a 52T chainring on a 26″ or larger tire then the odds of having to replace that nylon gear are slim to none.

I have heard of only one failure without using the throttle and that was with the above setup.

Karl

LikeLike

this is very similar to the nylon gears that live in the middle of BMW electric seat motors. either the Germans are cheap too, or there is something to be said for quiet operation.

LikeLike

BTW, THANK you for an excellent DIY write-up. This library will be incredibly valuable as this industry matures.

LikeLike

hi karl my bbshd melted its 3rd nylon gear at 3280 watts using E.R.T 82v 40amps it lasted 100km i am having a new gear with clutch made with case hardened steel at a company call HPC Gears Nicky Sungec

nicky@hpcgears.com i think the sweet spot for the bbshd 2500 watts but it will still destroy the nylon gear over time or if you set off in the wronge gear i am kind of like a test pilot the gear will be a one off costing around 250 pound if it works i will let you now and if any body interested in buying a new metal gear the more we order the cheaper they get would be good about 50$ but i think maybe it could be more like 100$ to share the cost from the one off sample they are making it from the original nylon gear thanks Michael Green

LikeLike

Sweet, I’d be interested. Let me know how it works.

LikeLike

will do

LikeLike

hi karl a little bit of advice to any body buying a controller from E.R.T 100v 50 amp 12 fret make shore that they adjust the shunt to work with cycle analyst it come set standard 1. ohm need to be adjusted to 1.6 to show the right amp and watts and of course if you are using the cycle analyst to set the maximum amps into the motor the shunt need to be correct when i fitted the E.R.T controller on my bike it was show 4800 watts i got in touch with Alan by email he told me he would get back to me with the correct setting i am still waiting in the end i went on to Grin web page on programming the cycle analyst and got the setting hope my experience help others thanks Michael Green

LikeLike

hi karl got the price from english gear engineer 150 pounds each but we have to buy 100 that 15,000 pound i told them i would try some where else the one off sample is 285 pounds plus 50 pounds delivery a bit to much for my budget

LikeLike

Luna cycles should have you do all their tutorials. All theirs are halfass or they refer you to chat forum. Is there anyplace you can by a replacement nylon or metal. Luna is out the most important gear. So my bbhd just sits. Thanks

LikeLike

Luna started making these but not sure if it’s aluminum or not… Looks like steel though.

LikeLike

They are steel, I have one to test, will do an article in about a week.

LikeLike

Pingback: Hallelujah : The BBSHD Steel Gear Is Finally Here | ElectricBike-Blog.com

Pingback: Quit your whining : How much ebike motor noise is too much? | ELECTRICBIKE.COM

Pingback: Pare de reclamar: quão exagerado é o ruído do motor da ebike? – La Revolucion de la Bicis Electricas

Great article. Looks like 3 options for gear replacement are now available on Luna – ludicrous steel primary steel gear, silent peek primary gear and a secondary bbshd steel gear. 1) Am I correct in assuming the primary and secondaries can be used together? 2) what are differences between ludicrous steel and silent peek? When would it be preferable to choose one over the other?

LikeLike

Pingback: Aleluya: el engranaje de acero BBSHD finalmente está aquí - MOTOS RECARGABLES