With the introduction of the BBSHD, I had expected that the BBS02 had reached the end of its product lifecycle and would be quietly retired away. To my surprise, Bafang did a complete redesign of the BBS02 without telling any of its US based dealers what they were doing and released it without any fanfare. The new BBS02 version B has a totally different case, controller, nylon gear, pinion gear and bearing sets that are completely incompatible with the BBS02 version A. Not only that, the new controller has different firmware that does not work with ‘Karl’s special sauce’ the programming settings that all of you have gotten to know and love by now. This article will explain the differences that I’ve found with the BBS02 version A and BBS02 version B and explain how to program the BBS02v2 so that the PAS will work properly with the newer controller. We will also discuss how to go about getting the correct parts for your BBS02 version B in the event that anything should break.

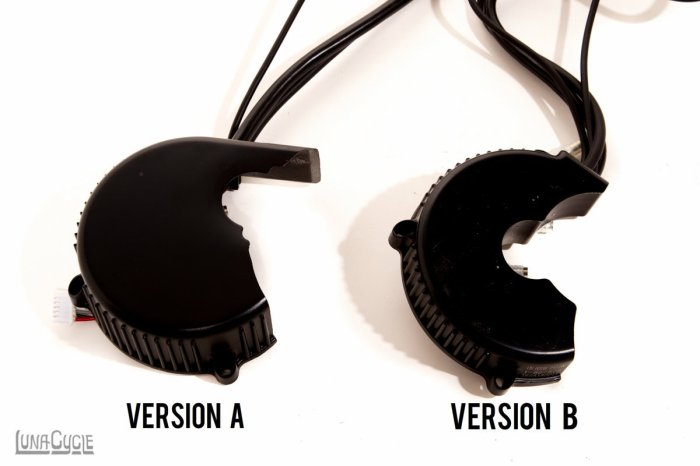

Don’t know what version BBS02 you have? Closely look at the shape of the controller and it will be obvious. Version B sports the evil PacMan look. Wagga-wagga-wagga.

The BBS02 750W version B was introduced without notifying US-based dealers that the changes were coming. The pictures on their website at some point switched over to the newer version B, but that was it. This became quite a problem, as Bafang will only allow dealers to order spare parts for their drive units while they are in the middle of a production run. Bafang finished their production run for the BBS02 version B with an entirely new part set and released it out into the wild without selling spare parts for the unit to US (or Chinese) dealers. Since Bafang won’t even talk to anyone who doesn’t want to buy $500,000 worth of drive units at a time, this has left everyone out in a lurch.

The v2 of the BBS02 has a new rubber washer at the end of the axle that I have yet to figure out how to get past without completely destroying it.

To further complicate matters the new controller for version B had different programming that would cause the PAS to not function properly if the “Time Of Stop” variable on the PAS programming page was set to less than 10. Since I have been touting ‘Karl’s Special Sauce’ as being the best thing since sliced bread, and those programming settings had a ‘Time of stop’ setting of 5, pretty much anyone who set their version B controller to my programming settings was sure to have a flakey PAS that would pretty much not function properly. This was less than ideal.

I’ve updated my programming page to reflect a ‘Time Of Stop’ of 10 on all my .el files and images, but I have to admit I’m still a little miffed at Bafang. I haven’t had much of a chance to test the programming on the BBS02vB but it seems pretty similar to version A. I’m guessing the Time Of Stop changes happened when people kept complaining that when they stopped pedaling the bike would keep going for quite a ways. If you don’t have ebrakes that immediately cut the power this can obviously be a safety issue. You basically end up having to brake against the power of the motor until it shuts off even though you’re not even pedaling. Instead of fixing the firmware variable settings they somehow changed the programming on the controller to react differently to the same settings (factory default for TOS is still 25 on both versions).

You can clearly see the differences in version A (left) and version B (right). The circular plate is different as are the pinion gear, bearing & nylon gear.

The procedure for taking the drive unit apart is nearly identical for the two units. The version B also has a rubber gasket that mates the controller to the housing to keep out water. The only other difference I found was that the Version B does not have the rubber plug above the circular plate that houses the nylon gear. The nylon gear seems to be an identical shaft diameter but the offset of the gear is different. I mounted a Version A nylon gear into a Version B unit and it was very clear that it was not going to work properly. The pinion gear is also very different and not interchangeable between the units. When you are ordering parts to repair your BBS02vB make sure that your Bafang parts dealer has some idea of whether the parts they are selling you are for Version A or Version B. If you start talking about the different versions of the BBS02 and the dealer seems to not know what you are talking about then you should probably find another dealer to work with. Right now Lunacycle has most of the different parts for the Version B drive unit, but they had to threaten to cancel a million dollar order to get them. A million dollars, that’s just crazy talk. At this point, Chinese companies are actually buying replacement parts from Lunacycle because it’s the only place they can get them from. What a funny twist of fate. I am still totally amazed that in less than a year Lunacycle has grown to be the biggest Bafang Mid drive reseller in the US to the degree that some Chinese Bafang resellers are buying parts from his US-based business. Go Eric.

Even with all the shortcomings of the BBS02 it is clear that Bafang is committed to the 750W platform. It doesn’t make sense that they would spend all the money they spent on retooling the BBS02 if they didn’t think they were going to make a whole lot more of them. I didn’t see anything in the Version B that would lead me to believe that the BBS02vB is going to be any more robust that the Version A. That being said I still have 10 ebikes with the BBS02vA that I beat on pretty regularly. The BBSHD still needs a dramatic increase in power for it to remain competitive in the marketplace. I suspect that Bafang will release a 35Amp version of the BBSHD at some point at the end of this year or early 2017 which I believe whole-heartedly that the BBSHD platform can easily support in its existing state. Keep in mind this is entirely speculation, but I believe it is coming.

You can see clearly that the offset is different between Version A on the left and Version B on the right

Does it still make sense to buy a BBS02 750W drive unit? If you are trail riding on singletrack I would say that the BBS02 still holds its own against everything else out there on the market. If you are building an electric cargo bike or a tandem or if you want to run the drive unit at full throttle all the time then the 1000W BBSHD is a safer bet. The mid drive market is heating up with the release of the 3000W Tangent Ascent which is one of the most fun mid drives I’ve ever tested. Dave from Tangent is putting together a 6000W Astro 3220 based Ascent drive unit that I’ll be installing and testing in the coming weeks which I have high hopes for. Normally 4000W would be the most power that any sane person would want to put through a bicycle drive train, but I’m not a sane person. I live only to destroy, rebuild and destroy again.

Ride On.

Are there any performance differences? Is it lighter? Better made?

LikeLike

Not that I can tell.

LikeLike

Sounds like Bafang just wanted to build a better street legal mid-drive with a true 750 watts.

LikeLike

Does it have better sealing for grease, because I’ve ordered 750w bbs02b and Already orderd mobilgrease 28 😀 to regrease everything before installing the kit. Just wondering.

LikeLike

The new bearing does not look like it will be any better at keeping the grease from migrating to the primary any better than the BBS02vA. I have not tested it though.

You can always regrease just to be safe. It’s much easier to just do the secondary side which only takes 5 minutes. Just wipe off all the grease you can and pack the primary side with the mobilgrease 28. That is probably all you have to do.

LikeLike

I’m thinking only regrease the secondary side with mobilgreas 28 and check after a while for any leaking drama to the primary side, if its any better than the old model.

LikeLike

Since it is red colored so it shows if it leaks into the primary side, just for fun u know. Then I’ll grease both sides with mobilgrease 28.

LikeLike

VERY DETAILED,

LikeLike

The “rubber washer” is a standard lip seal quite common on industrial electrical motors and pumps its made out of a steal with rubber on the outside. On the other side it should be marked with the outer and inertia size of the seal. Just putt a small flat screwdriver between the motor housing and the outer part of the seal and pry it out, they are sheep to replace try to get one with viton rubber they are much more resilient against petrolium based products.

LikeLike

I ordered a bbs02 from Paul that I received two weeks ago. I must admit that I was a bit dumbfounded when I used your instructions to take it apart for a regrease and a lot of things differed between the instructions and the actual motor. Now I know why 🙂

Guess it’s a good thing I hadn’t gotten around to do the programming stuff yet!

LikeLike

Does the new BBS02 have a gasket on the metal gear side like the BBSHD? If so take care not to damage it. At least one kit builder with a BBSHD tore the gasket and water migrated into the motor.

LikeLike

Version B is shit! Ive installed 3 version A’s with no problems! Installed my first B version on a customer and controller crapped out at 2.9km!!!! What a fucking joke! Theres nothing new or better with the version B so why the hell did they change it??? Please enlighten me and unboggle my mind!

LikeLike

I’ve installed 5 version Bs, only one controller failure, and it was because I washed an open power connector. Other wise all solid and running up to 5 years now.

LikeLike

Are there any indications that the new nylon gear is any more temperature resistant?

LikeLike

No

LikeLike

they’re obviously just hoping that people buy the wrong parts so they have to re-buy more parts

LikeLike

Could you show us the way you are taken off the cover plate on a BBS02B. I have try and was not able to lift the plate.

Thank’s

LikeLike

Bafang seem to say the upgrade to version B has improved “waterproof, stability, power, energy” the waterproofing upgrade catches my eye, has anyone had problems with this on the A version? I’m in China and looking to buy my first mid-drive, I am trying to decide between BBS02A, BBS02B and BBSHD.

LikeLike

Hi according to a BaFun distributor in China the new B model has improved waterproofing. Any ideas if this is true? I am looking to get my first Mid-Drive and wonder whether to choose the BBS02A, BBS02B or push the boat out and go for the BBSHD. Thanks.

LikeLike

No idea.

Sorry

LikeLike

Ive used both BBS02A and B. The BBS02B lasted 30km. Needed a new controller and just recently gave me an error code 21! Easy fix but annoying! My BBS02A is still running. Waterproof wise ive never tested either. Next trial is BBSHD nx year. I hope this one last the longest.

LikeLike

as ebike retailer im totally worried about your comment, Im about to give two kits bbs02 B to customers, and you saying that they will probablly fail at 30km… shit, this is real bad news man.

LikeLike

I have done just over 200 km in August on my BBS02B with no problems what so ever. You are always going to have some percentage of failiur in a production series, overall i can’t se major reason why the b version who’d be of less quality. The materials chosen in the constructions seems to be the same with minor redesigns of the components. Overall i think Bafang have made a good product they just want to make more money and that’s why they have rediaignd it with a minimal of compatible parts.

LikeLike

Gilvoni almost all chinese products has lemons. Maybe you will be lucky that you get two good ones. All im saying is if your using a bafang kit, you MUST have spare parts. I built 3 bikes this summer and that one was a lemon. I still build them because i give my customers warranty on parts.Which i have in stock. If you research endless sphere theres always a solution to these fails. With the right grease the motor itself almost never fails. Its the cheap components that comes with it that will always fail first. So have spare parts!

LikeLike

I have had no issues with my BBS02vB. If you install them on a bike and ride full throttle all the time then whether you are running A or B it will fail. I would take user comments with a grain of salt.

LikeLike

Hi Karl, thanks for a very enlightening site. Could you please elaborate on why riding “full throttle all the time then whether you are running A or B it will fail” ? Do the controllers have a design flaw that makes them overheat ? I have just aquired my 3rd controller to the 750W 48V model, and by mistake I have gotten the version b of the controller (my unit is the a version). I have managed taking the controller out of it’s ver b casing and into my ver a casing but the unit will only run at PAS 3 and intermittently – any suggestions ?

LikeLike

Yow I have no idea. I don’t know if the A and B controllers are swappable. I would bet they are not.

My advice is to get an A version controller and use that. I’m honestly not sure if and where you can still get an A controller, I would check with Paul from California Ebike and also on alibaba and aliexpress. Good luck.

The BBS02 is 1200W peak power, but nothing in the drive is designed to run at that power for very long. If you peg the throttle for several minutes uphill you will destroy the controller or melt the nylon gear, guaranteed.

LikeLike

You could try to check from a vendor if PAS disk is different between A and B models, and eventually buy and replace your A with B, hoping that sizes are identical. Pas disk is cheap, you can find it here for example.

greenbikekit.com/electric-bike-kit/central-motor-kit/bafang-bbs-spare-parts.html?limit=45

LikeLike

hi giorgio,

i think i have the controller you need. i killed the motorcoil of my bbs02 750w produced 2014, but the controller is ok. i´m very sad that this happened, although i created a great cooler on the motor. but too much is too much. so i am looking for a new statorcoil for this motor, but didn`t find yet, on the other hand i could imagine to sell the whole parts. the problem is maybe our distance, i´m from austria, and you?

LikeLike

Hi Midmatt,

thanks for the reply. I live in Denmark and I´m interested in buying your bbs02a 750W controller. What is your price ?

Best regards,

Thomas

LikeLike

this would make sense

LikeLike

hi thomas, i think we should talk this by phone. if you send me your number i will call you back

LikeLike

Hi Midmatt,

thanks for your reply. My mobile phone is +4530241743. Looking forward to hearing from you.

LikeLike

Karl

Any further updates on custom programming for the B version ?

LikeLike

i just installed my first new BBS02B with a 965 display and i had issues with the motor pulsating (on and off that shakes the whole bike ) at low speed start on PAS but problem goes away as i pedal to increase to faster speed.

I have made a dozen of BBS02 bike conversions without any issues.

Have anyone experienced this? Can this be programming setup?

Hope someone can help me since Bafang and my supplier in china does not respond to my email.

LikeLike

Karl,

Have a question. I’m considering get a mid drive for my FS Commencal mini DH 2009. But I’m between BBS01B and BBS02B. I prefer the BBS01B because it is lighter. I do some DH with jumps and stuff and weight is an issue.

Is the extra weight worth it?

LikeLike

I would only consider the BBS02 for any build I did.

LikeLike

i have a bunch of ego tool batteries… figured i would use them for my first foray into ebike

is bbs02 the best ‘bang for the buck’? occasional city travel is the extent of what i plan to do. the cheaper the better, so long as it is confirmed to be compatible with these ego’s i already have. i plan to initially slap it on an aluminum walmart-bought schwinn that is basically new but just collects dust

LikeLike

I’ve bought a lot of hub motors over the years, but mid drives are all I ever ride. The BBS02 will not disappoint.

LikeLike

Any updates on longer testing of the BBSo2vB?

Thanks

LikeLike

I have on of these BBS02B that I bought from Paul in august. It was manufactured in april 2016.

I have ordered a circular plate from Doug that I have now to return. I’m in Canada and postage is $33 for a

$15 part!

Also I received a large gear from Paul and it just doesn’t fit in. Way too large or different geometry.

What a bummer.

I’ve documented it at endless sphere for those interested. Several photos available there too.

https://endless-sphere.com/forums/viewtopic.php?f=28&t=58898&sid=3c5856ba8084da7ad3d7ae39f4ac1569&start=900#p1260795

LikeLike

I purchased a bbso2 version B and within 24 days my internal nylon gear peanut butterI’m wondering if it was due to me packing the secondary Gear with the moly grease now I just got another bbso2 virgin B and I am going to pack it with the mobile grease 28 and hope for the best does anyone know if the internal gear went out on the first one due to the black moly grease used

LikeLike

I’m brand new at this e-bike thing, and I’d just like to say “holy crap”, there are so many things to consider ! I Hate to sound stupid but here my predicament, Just recently bought an E-bike it has a Bafang bbso2 mid mount motor, not sure what version, and its gone hey-wire. It just out of the blue decided it wanted to be unpredictable. I was in PAS 1 just starting to pedal and it took off 0 to 24 in 3-4 sec, stop pedaling and the speedometer goes rapidly back down to 0 then the battery symbol on the display starts flashing and then NO POWER. I charged the battery and now the darn thing will not even turn on. I love this bike, I’m addicted, its been four days and I need a ride !!! Can anyone help, suggest something to try ? How do a know if I’ve fried my controller ??? Thanks for reading !

LikeLike

Talk to whoever you got the motor from.

LikeLike

I just received a new BBS02 and it had two small short wires out of the motor black and black with white stripe. Anyone know what these wires are used for? They have small female spade connector. The wire is about 24 Awg.

LikeLike

I think that cable is for lights 6v maximum 300mA gets turnd on if you hold the + button for a couple of seconds along withe the back lighting on the display. On my motor it is a red and black wire the white cable was cut off.

I connected it up to a relay and a fuse and used a buck converter to get a voltage from the battery that I could use for a headlight.

LikeLike

it is using for the 6 V light, recently the bafang factory will updated the motor with the 6v light cable and the gear sensor cable.

LikeLike

These are for powering a front headlamp at 6v

LikeLike

dear karl!

thanks for you and your job in this page, this is really great what you have done!

i´m from austria and have experience with 500W and 750W bbso2. me and friends we drive since 2014 with bbso2. one bad experience was the controller of the 500w/36v motor, one mosfet of p75 had to be changed.

because of your explaination we could repair and since one year it runs properbly.

with a bbs02 750w motor (2014) i had problems with overheating motorcoils and damaged pinion after about 400km!

the steel of the pinion was not hardened, it had only 52 hrc. i bougt a new one and hardened it up to 62 hrc, now it runs since 4000km perfectly. but i lubricate it every 100km with 1ml gearoil, so it is always fresh lubricated. during this change i saw the coil, it was darkbrown, overheated, but was just working.

i installed a coolerplate. it is made of 99.5 aluminium 6mm thickness. i produced it with a cnc millingmachine and assembled it betwenn the conroller and the gearhousing. after this the motor is about 15 degree colder than before. i can really suggest for everybody.

the newer bbso2b becomes also too hot, but the case of controller is otherwise. is there any other way to get it cooler? does it switch off if it gets too hot?

LikeLike

There is supposed to be some kind of thermal cutoff for the Mosfets, But I’ve never hit it and I’ve gotten them plenty hot.

LikeLike

well firstly many thanks for letting us all know, I have a broken freewheel clutch ring and been going a bit mad here as everyone has been saying “just pull the rubber plug out and untie the locking nuts”. well there aint no way past this thing. I took all the rubber off, it appears to consist of an inner sleeve that is pressed in to keep the washer down. its hard as anything and no screwdriver or the like will shift. I took it to my car guys and he tried pressing it out but gave up. This is a serious screw up, this clutch ring is a very common problem, loads of vids on how to replace it. Well you cant now without cutting into the machine. I’ve screwed mine by following a national sycle route here in the UK that took me and my naive backside along a beach, got sand everywhere. Cleaned it up after my cycling mentor and engineer told me off, but the damage i guess was done.

I am ahead of the curve, I can break anything in double quick time. But by the end of the year I wont be the only one complaining. *HELP*.

LikeLike

I tried small screwdrivers, exacto blades with no luck. The only thing working for me is a needle. You can pry it out with a needle but you’ll end up with a bended needle. Ho[e that helps.

LikeLike

I took a dentist’s pick and used that, worked well. You can buy dentists kits online cheap.

LikeLike

its not the rubber bung, mine is even worse. here are a couple of photos. it is a washer, originally with 1 or 2mm or rubber coating which i have scraped off trying to get further. It appears be be secured with a sleeve inside the shaft. It is not budging and I dont really want to start attacking it with a drill just yet.

it was built end of november last year.

LikeLike

i cant post a URL right now, so you will have to imagine a steel washer and fixing sleeve. It’s been to two engineers, my car place and my nuts and bolts place. Car guy tried pressing it out, nuts and bolts man wasnt happy about drilling tapping screws into it either. freewheel clutch broken, new one in the post but it wont help if i cant get in.

LikeLike

its not the rubber bung, mine is even worse. here are a couple of photos. it is a washer, originally with 1 or 2mm or rubber coating which i have scraped off trying to get further. It appears be be secured with a sleeve inside the shaft. It is not budging and I dont really want to start attacking it with a drill just yet.

it was built end of november last year.

LikeLike

I’m pretty sure I have the same – http://www.ts-export.com/_mb/bbs02_31dec2016/IMGP0376.JPG

Not easy to remove, but definitely pryable.

LikeLike

thanks, but isnt that a rubber plug/seal 1cm deep. mine is a steel washer. there is no way you can move this without drilling into the washer. where exactly did you pry from ?.

LikeLike

insert a needle between the frame and the washer (external edge of the washer. it will do it’s way into the rubber around the steel washer then bump into the frame where the internal diameter is smaller. you’ll reach an edge where the washer is seated. it’s clearly visible on several pictures.

it’s not a rubber plug 1cm deep, 2 mm thick max. i removed it twice so far, last time was 3 weeks ago because strange noises were coming from the unit was hot. it’s a challenge every time.

you can drill into it if you want to and purchase some new. they’re readily available online for around $3 but I strongly suggest you try with a needle first. the washer will lift just a little bit at a time so you’ll need to keep moving the needle around until the washer is tilted enough for you to insert a stronger tool, screwdriver, long nosed plier. whatever to remove it completely. the hardest part is getting it to tilt with the needle. be sure the needle is inserted the farthest you can before prying or you’ll just destroy the rubber.

LikeLike

increased thanks. i’ve mummified it in bubble wrap in order to send back to where I got it. there is no way you can get round the outside of this washer. you might be able to get into the inside , but you’d destroy the rubber around the spindle (the inner black ring is rubber on the spindle). the outer ring, which still has rubber on it, is a flange, its not rubber, i cant get anything past that.

LikeLike

It is just a standard radial shaft seal just pry it out with a flat screwdriver and replace it. Tap the screwdriver gently down with a hammer between the housing and the seal and deform the seal by bending it inwards then it is easy to pry it out. I have done this on oil lubricated vane vacuum pumps hundred of times. Try to replace the seal with one that have viton rubber it’s more resilient against oils. The messurement’s are marked on the rubber on the other side of the seal (inwards).

Good luck with your project.

LikeLiked by 1 person

damnit henrik. i’ve bubble wrapped the entire thing up!. nobody would admit to my sleeve theory. OK, I will de-mummify and have another go. thanks both.

LikeLike

some images

the edge is visible here http://www.ts-export.com/_mb/bbs02_31dec2016/IMGP0401.JPG and there http://www.ts-export.com/_mb/bbs02_31dec2016/IMGP0407.JPG

the removed washer is visible left to the word Chaudiere here http://www.ts-export.com/_mb/bbs02_31dec2016/IMGP0402.JPG

LikeLike

yes, its the same. cant get any further till i get the locking not tool. i could try those curly pointy pincers but it does seem quite tight. tool is on its way from shenzen.

LikeLike

I’m in. just bang away on the outside of the washer till she buckles. thanks for you encouragement

LikeLike

hi karl,

i have once more a problem with a 36v 500W bbs02 controller, i changed 2 mosfet about 1 year ago, but now the next one is broken. these are the p75 types , as you write they are bad in quality.

can i change them (all 9) to the irfb3077 ?

please let me know what to do…

thanks a lot

matt

LikeLike

I would just buy a $60 replacement controller and pop it in.

LikeLike

dear karl,

i have no controller found for this motor in europe. the only one i found is a newer version, it seems that is for bbs02b. so i have no other way to repair the old one. is it possible for the 36v 500w system with the irfb3077 mosfet?. i just disassembled the old controller and soldered the old mosfets off, so it will not be a problem to solder the new one.

LikeLike

Hi

I ordered within two month from the same dealer in China a BBS02. Both are BBSO2B as per the print on the motor case.

However, the first one had three cables coming out of the controller (conncetions to battery, display, and speed sensor), while the second one now has four cables (one additional one with a yellow connector) which I presume is for connecting a gear shift sensor (that’s how I set it up and it works fine). Pretty handy.

Any idea whether there is any other difference between the 3-cable and the 4-cable B version?

LikeLike

Usually it’s a headlight plug.

LikeLike

nope it’s a gear sensor plug

LikeLike

Hey I just purchased my bbso2 from luna and programmed it with karl’s special sause and it seems to work just fine. Also,,, pretty sure it’s the “B” version because i just purchased it 2 weeks ago. having said that i’m pretty new to e-biking and truth is even with PAS on i can just hit the throttle and it works. In other words no matter what PAS i’m on (1 or 9) if i need more power i can just hit the throttle and it works. no idea if that’s supposed to be like this or not

LikeLike

Pingback: Electrify Your Family | dandyhorse magazine

Hello Karl, hello to the other users,

the reason some of the new BBS02B units fail after a few kilometers of driving for some of the commentators here is pretty simple: the controller is – as usual – filled with a breakable putty-like mass. This doesn’t result in a problem but there’s more: the MosFETs are mounted on the primary cooling half-round aluminum piece, which is a good intention for quick assembly.

This piece is “mounted” and guided on assembly by two aluminum “slits” on the sides of the controller case cover. The problem starts here.. It oftenly does not fit in a term which would connect its outer rounded edge on the middlewith the case cover. Instead there is a clearance gap between the middle area of this aluminum piece and the case cover of about 0,5 to 1 mm – which is in the process then filled with a thermally more or less isolating putty mass.

The thermistor is placed more on the right side of the controller, so it might still be dissipating enough heat in this more connected part and stay cooler than the middle placed FETs, which will not be able to dissipate their heat quick enough to the case cover, as there is the isolating putty-like mass.

This will oftenly cause a burnout of one or more FETs in the 9 FET array of the BBS02B.

The ideal solution would be (if included in the manufactoring process of Bafang) to have three or four threads cut in the inner aluminum piece between the mounting threads for FETs, three fitting holes in the case cover and three screws which are (after insertion of the controller, but before putting the putty-like mass in it) then torqued so the inner aluminum piece is pulled to the case cover with a pretty high force. This, combined with a thermally conducting thermal adhesive or mass would optimize the thermal dissipation at around five to seven times better.

I have heavily modified the BBS02B myself and the thermal dissipation is a dream (after replacing the inner thermal mat with something of quality). See images, if interested.

Friendly regards from germany

Wolf

LikeLike

You have any more pictures or video’s of this? Sounds very intresting.

LikeLike

Hello Harminder,

I made several pictures, but didnt post the modification process on any website yet, except for two, three images. The modification of this one model is completed (at least with the BBS02B) and at the moment I am missing the time for other BBS models and their modifications.

If I write a topic about the modifications in one of the forums used, I will post the link here (if Karl does agree / allow this).

Here are some more pictures from the modification:

I also analyzed the “night mode” pin layout of modern BBS displays, which will switch several signalling lines on the PCB (but one should add another transistor/FET protected load circuit afterwards to switch higher loads over this just mA-wise signalling lines) for usage of external headlights or light systems.

This is basically upgradeable if one knows how and what to do with it – but most people using the BBS system wouldn’t want to tamper with the controller PCB (let alone freeing it from the putty masses) I guess.

As you can see on my pictures, I integrated several connection possibilities on the outside (and made all cables modular for easier swap-on of the motor block or defective cables on different fully-integrated bikes), so I could use several of the “onboard”-functions not usually accessible from the outside, as well as the two additional thermistors which I installed.

Friendly regards from germany

Wolf

LikeLike

Hi Wolf, really like the work you made with your controller, can you list the parts you used (connectors mainly) and from where you got them? A good source in europe/germany for the Mosfets would be good. Have a blown controller to fix.

LikeLike

Hello Giorgio,

the parts/connectors were mostly selected for the reason of size and fitting together as much as possible contacts with compatible ampere ratings.

Aside from the XT60 main connector, the red dual-bulledconnector plug (available on Hobbyking as example) and one 6 pin MPX-connector (widely used in RC) there were industrial connectors used, which are high priced but of high quality, lightweight and waterproof (open connectors need sealing plugs therefor).

See there: https://www.binder-connector.de/de/produkte/subminiatur-steckverbinder/snap-in-steckverbinder-ip-67/

Prices per single plug range between 5 and 15€ mostly.

Best regards

Wolf

LikeLike

Hi Wolf, do you mind sharing a picture of the backside of the pcb? I’m repairing some blown smd components and can not read the values anymore.

LikeLike

Hello Peter,

sure, but I don’t have extreme high resolution makro shots of the single SMD parts. Most parts are still acceptable readable:

Best regards

Wolf

LikeLike

Great work, the cooling fins are something I was planing on doing myself.

So the circuit has a protective thermistor, just not maybe on the optimal place? What happens when triggered? Cuts out completely or just limits the power?

Have you bothered to upgrade the mosfets as well (CSD19536KCS)?

Did you replace the putty mass?

LikeLike

Hi Carlic,

the controller board has a protective thermistor in / at the first aluminum cooling curved plate around the MosFETs, yep. No thermistor for the motor stator / rotor unfortunately.

The first versions of the BBS02B had a noticeable gap between the curved cooling plate and the outer aluminum case, which was flooded with putty and not cooling well due to this case (thermal isolator inbetween).

In the newer BBS02B (since 2019 with different model name, but same product) they seem to have undergone some fix / correction, as the rounded aluminum plate sits better and there is rarely putty between the two aluminum plates.

No idea if the controller cuts off completely or just reduces power if the thermistor gets too hot. Never came that far after modification.

The MosFETs in BBS02B are already much higher quality and more efficient than the ones in BBS02(A), the model type used in BBS02B was formerly used to mod BBS02A models.

Best regards

Wolf

LikeLike

Would you be able to convert A to B? Is it possible to buy new

https://lunacycle.com/parts/bafang-parts/bbs02-parts/bafang-bbs02-circular-plate/

https://lunacycle.com/bbs02-mid-axle-assembly/

https://lunacycle.com/parts/bafang-parts/bbs02-parts/bbs02-pinion-gear/

https://lunacycle.com/parts/bafang-parts/bbs02-parts/bafang-bbs02-nylon-reduction-gear/

and fit it to A? I will need to replace everything anyway.

Is there any other changes in motor casting which won’t let me do it? I don’t have both so it’s difficult for me to find out (mine is from 2015 so it’s not so old).

Would you write something about it on your blog?

I would be able shave few mm if needed.

I need to rebuild that motor and right now there is no straight answer what is compatible with A.

LikeLike

No, just buy a new BBS02, it’s much easier and probably cheaper.

LikeLike

Hello Greg,

I think this is pretty much impossible, as the motor casing is different and even most of the parts are modified in the BBS02B (not neccessary in a better way, but still modified enough to not fit in the other aluminium casing).

As Karl wrote: Just buy a BBS02B unit – maybe with a broken controller or broken nylon gear, if you want to tamper with it anyways (the nylon gear is on some shops available for order, most other parts are only rarely available for standalone purchasements).

Best regards

Wolf

LikeLike

Please don’t think. I already received correct answer from main leading shop. It is possible with new plate (12mm). I will have to replace all gears (which are damaged) and all will fit in. I don’t get it why you thinking instead of knowing, it will ruin your business as nobody will buy anything from company which claim it’s easier to buy whole new motor.

Who told you it’s different casting? where is different?

LikeLike

I wonder if you did not read Karls blog entry, the whole controller side casing is visibly different. Nobody “told me”, I disassembled the motors myself to compare them and recognized lots of differences.

If you are not going to change the controller, have fun fitting the reduction gear parts manually.

Weird idea that something ruins “my business”, if you have not even the knowledge if such exists (it doesn’t).

But thanks for the “professional business help” from someone who obviously hasn’t compared the casings, let alone the rubber seals, sensor placements and other aspects. I wish you good luck sealing the nylon gear fat against the second gear reduction stage.. 😉

Regards,

Wolf

LikeLike

Sorry Karl, obviously wrong column.

Best regards

Wolf

LikeLike

Hey, does anyone tested bbs01b 350w for an extended period? I just bought one and wondering if I should regrease 2ndary gears first? Thanks

LikeLike

What’s the amp rating of the standard controller on the new BBS02, I’m planning on using the Bafang from my Biktrix for a build. Thanks

LikeLike

25

LikeLike

Hi! You list a lot of differences between the A and B models, but what is the same? I have an A model that has a blown controller and am just going to buy the B model to replace it with. I want to salvage anything I can from the A. Thanks for any help you can provide!

LikeLike

I tried that, but it doesn’t work. The plugs are the same and can physically be connected, but:

1/the controller housing is incompatible

2/The motor runs erratically

LikeLike

Thanks for responding to an old thread. I think I didn’t make myself clear. I bought an entire BBS02B motor assembly, not just the controller. I want to know if there is anything off the old motor worth saving or should I just bin it? Thanks much!

LikeLike

I save everything but that’s probably stupid.

LikeLike

Thanks again. I guess I’ll do the same, although it doesn’t look like there is much that remained the same. The things that remained the same seem the least likely things to fail, but you never know.

LikeLike

Could it be that the bbs02b has 160Nm torque, where as the normal bss02 has only 120Nm ? Another difference or bad listing of the sellers…

LikeLike

They feel about the same to me.

LikeLike

Hi everyone I have bbs02b. I saved the stock file before I altered the system with Karl’s special sauce it played hell with my system so put stock firmware back on but now every time I press throttle it just bogs down. As any one got pictures of the default settings please because I don’t think my original saved tidy.

LikeLike

This may be a silly question, but I’m assuming the mechanical dimensions of the A & B are identical?

Thank you,

CMJ

LikeLike

I have a BBS02 Version B 750W and was looking to remove the drive wheel to clean out and re-grease. Unlike most videos on You Tube the drive shaft doesn’t appear to have the 2 castellated nuts below the seal. It looks just as described at the start of this blog and I had to destroy the seal to find this out which is annoying.

Is this shaft a press fit in & out as I can’t see any other way of removing the shaft. I tried gently tapping the shaft but seen no movement. I’m worried about damaging the casing if I attempted using pullers so would be grateful for any advice on this.

Paul.

LikeLike

Aiutatemi …..ciao a tutti volevo qualche informazione riguardo motore BBS02B 48v 750W percorsi piu o meno 150 km senza forzare pedalare tranquillamente dopo qualche giorno mi accorgo di non avere piu la potenza di prima sembra meno di un 250W non porta nessun errore i parametri sono ok la batteria ok potrebe essere il controller? GRAZIE

LikeLike

I was looking into bafang, but with this information i will no longer do so! What were they thinking, releasing it without another name? Were they thinking at all? It will get fucking complicated to get the right parts…

Seems like everything else in this world, what worked, or what was coordinated will be messed up big time…

LikeLike

I have one of the new BBS02B 500w Bafang mid drives which has done 3500kms. My PAS no longer works although my throttle is fine as is the Walk Mode. This all seems to stem from an overheating episode when my motor was too hot to touch after about 25kms. But also after I had used the Speeed app to re-program my motor. Is there a setting which can possibly cancel out my pedal assist besides the Stop Delay which is set to 250ms?

LikeLike