In so many ways Bafang’s BBS02 750W drive unit is a dream come true. Almost anyone with very little technical know how can order a drive kit and 48v-52v battery pack and have it installed and running on almost any bike with 2-3 hours of work. Any other mid-drive ebike kit is going to take a lot more time and energy to install and get working properly. The problems arise when things suddenly stop working. Take a BBS02 drive unit into almost any bike shop that doesn’t specialize in ebikes and the owners will just probably shrug their shoulders and tell you that you’re on your own. This leaves most BBS02 owners with the difficult task of troubleshooting and fixing their own technical problems. This document will guide you down the often times confusing path of figuring out why things aren’t working right and hopefully get you pointed in the right direction to get it fixed.

Want to figure out all your problems? Buy 2 identical drive units from the get-go

As with any technical problem the first thing you have to do is break the problem down into a series of steps. Many of these steps will have you swapping out components that you probably just won’t have lying around. My advice when you buy a BBS02 drive unit is to buy two instead. They are relatively cheap and that will give you a bike you can ride with your significant other or friends with. You could also create a commuter bike and a trail riding bike. I am the proud owner of no less than 8 drive units mounted on different bikes and at least one of them is always broken at any given time. Having more than one drive unit is a great way to swap parts around and find out exactly what is wrong.

Get a cheap watt meter

When you start troubleshooting the BBS02 the first thing you need to figure out is the problem with the battery or with the drive unit. Without a cheap watt meter this is very difficult to do. A messed up pack or a pack with poor electrical connections can often read full voltage with a normal voltage meter but as soon as there is any load on it the voltage can drop precipitously. With a watt meter in line between the drive unit and the battery it becomes immediately obvious if the problem is with the drive unit or with the battery. If the watt meter stays on when power is applied then the battery is probably fine and the problem is on the BBS02 side. If the watt meter shuts off then that means the BMS on the battery is cutting out and the problem is on the battery side. If you have more than one battery you can also try that on your bike which will work if you don’t have a watt meter. You can buy a 150Amp watt meter from lunacycle.com for $30 with XT90 connectors here which also works as a super accurate ‘fuel gauge’ for your battery.

Check your connectors

When you connect a high power battery it sparks, even if your pack is equipped with a spark arrestor. This continual sparking when connecting the pack can eventually destroy almost any electrical connector, even ones like the Anderson power-pole connectors which are designed with a sacrificial tongue. The higher your voltage is the worse the problem seems to get. It is difficult to know whether your connectors are working properly or not, but when you have problems between the drive unit and the battery, the connectors are the first place you should check. A visual inspection of the connector should show if arcing has damaged the contact points. If the plastic connector has started to melt or the contact is black and damaged then replacing the connector is recommended. I’ve recently fell in love with the XT60 (60 Amp load limit) and XT90 (90 Amps load limit) connectors and I’ve been using them as my new standard on my packs and drive units. If you’re having trouble with the Anderson’s power-poles then try high quality XT90 connectors purchased with pigtails and soldered onto your existing wires. Put the female plug on the battery side to minimize shorting risks.

Check the easy stuff first – like ebrake connectors

I’m a big fan of testing the easy stuff first and the BBS02 runs fine without the ebrake connectors. If the ebrake sensor is busted or accidentally active then the drive unit will not do anything when it is on and the display is active and you will think it is a dead controller. Unplug the connectors for both ebrakes and the Giant Green Button (if you have one) before testing anything else.

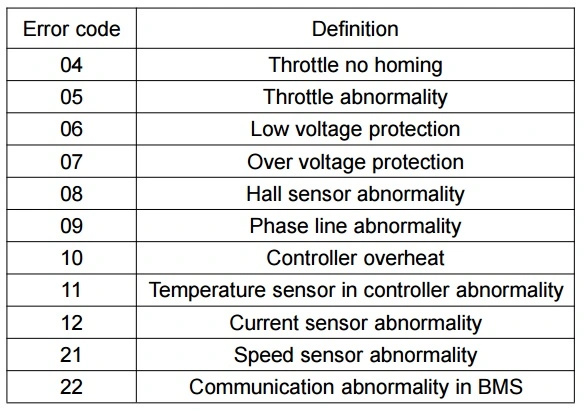

There is a infinitesimally small chance that you are lucky enough to have a code display on your BBS02 display. The most common of these codes is the 21 code which shows a problem with the speedo. The most common problem is that the magnet has slid down the spoke and the speedo is no longer working. I use a small piece of gorilla tape wrapped around the spoke and then locktite the magnet sensor down to the spoke as hard as I can. If your speedo magnet is gone the BBS02 still works just fine and if you want to shift PAS levels up or down just tap the ebrake and the 21 error will disappear and you can move up and down PAS levels for a few seconds before the error appears again. In all honesty I’ve never seen any of these other codes even though I’ve had plenty of low voltage packs and overheated controllers shutting down on me.

If you get an error 30 code you probably have a bad C965 display. Bafang had a run of BBSHDs with a large number of failing displays during early 2016. Swapping out the controller or cable is not going to help, talk to the vendor you bought the BBSHD from and get a replacement display. I’ve also heard of people having their cabling on the display break internally and getting the same 30 error.

You must take care when removing rear tires for service on fatbikes as the speedo comes quite far out into the tire area and can easily break when you try to force the tire past the speedo. The best course of action on fatbikes is to twist the speedo up or down out-of-the-way then remove the tire for service and then twist the speedo back after the tire is remounted. You should have about 5mm of clearance between the magnet and the speedo crosshairs area. The connector can be broken but still look fine from a cursory inspection. If you’re getting the error and everything seems fine then grab the connector firmly and wiggle it to make sure the unit has not broken apart and just appears to be fine from the outside.

Did my controller overheat and shut down or is the battery dead?

If your BBS02 shuts off itself after a lot of hard climbing and won’t turn back on until you disconnect the battery and reconnect the battery then you either

- Hit the low voltage shutoff

- The controller overheated

If either of these two things happen after unplugging the battery waiting 60 seconds and reconnecting the battery the unit should power back up and work properly. When there is no load on the battery the voltage will quickly recover.

If you don’t have a temp probe and you’re not sure if it shut down from overheat or low voltage then reach down and hold your bare hand on the drive unit casing. If you have a hard time keeping your hand there because it is so hot then you probably overheated the unit. Wait 5 minutes before starting off again, if you’re on a steep 20% grade hill then I usually will just walk my bike to the top as the motor cools.

Blowing the mosfets on the controller

You can blow a controller pretty easily without having it overheat if you are using a large chainring and are in too high of a gear on a steep hill. This is less of a problem with the newer mosfets, but it can still happen.

The controller is blown if the unit does not power off when it dies but instead you hear a bunch of clicks like gears skipping and then the throttle doesn’t do anything and you can’t hear any motor running at all when you hit the throttle. Some users report a very faint click when they hit the throttle which is the power cut out as the battery shorts to ground from the blown mosfets. The only solution to this problem is replacing the controller, preferably with one that has the newer mosfets on it which are a little more expensive at $100 but worth it. If the item description for the controller does not list the newer mosfets like this one from lunacycle, then you should ask the vendor what mosfets it has before you buy it. You can also replace the mosfets yourself with ones that don’t suck from Digikey but it’s not for the meek of heart and not recommended.

If the mosfets on the controller are blown you should feel a fair bit of resistance when you spin the rear wheel backwards and the tire is off the ground.

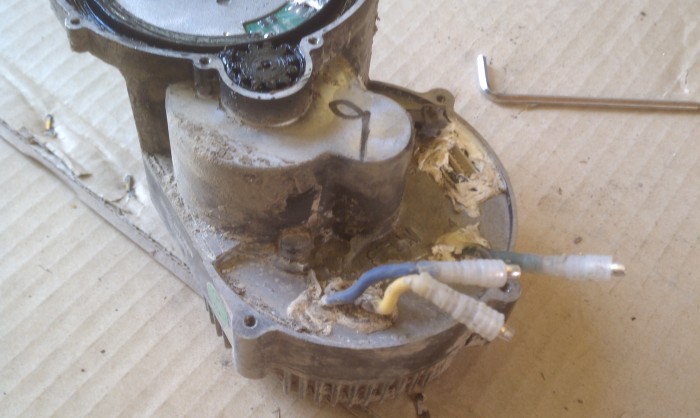

Just because the motor won’t work does NOT mean the controller is dead

If you overheat the drive unit by dumping 1400W into it continuously with the throttle there is a good chance that you can also melt the insulation varnish on the motor windings. Melted motor windings can lead to a motor that doesn’t power up at all and acts nearly identically to burned out mosfets on the controller. If your motor stops working and it has been under load the first thing you should do is put your nose right next to the unit and take a good long sniff. If the windings have burned out usually you can smell it for a short period of time after they fry. In contrast burned out mosfets will not smell at all. The easiest way to check to see if the windings are melted is to take the motor apart and do a visual inspection of the windings. If the windings are melted you should see black marks where the motor overheated and the varnish melted.

Best way to not fry or overheat your controller is with a temp probe

Most of my BBS02 units have a temp probe installed on them, the instructions for doing that are here. This allows you to know when the unit is going to overheat and to stop feeding it so many watts before it does. After several hundred hours of beating on the BBS02 with temp probes hooked up you will have a much better idea of what the drive units like and what they don’t like. What they really hate is being in too high of a gear with too slow pedaling cadence on too steep of a hill. Riding with a temp probe will help you learn what you can get away with, but as a rule of thumb just keep in a gear that keeps your pedaling cadence very fast when you are on a long steep hill. If you are using the throttle on power level 9 regularly then you must read this article on care and feeding of your BBS02 if you want it to not die a quick and untimely death.

My motor turns and I can hear it but nothing turns

If you are unlucky enough to have this happen then most likely the nylon gear has failed. It’s relatively cheap and an easy fix, the instructions are located here. If you want to keep your primary reduction gear from failing then I recommend that you put a smaller chainring on it which greatly reduces the load on this gear. If the nylon gear is fine when you take it apart then you should check the secondary reduction gears (both are metal so unlikely to fail) and also check the freewheel which is located on the main axle inside the large metal secondary reduction gear.

Be careful not to get any black heavy axle grease on the white wheel. This grease can break down the nylon and cause the gear to fail prematurely (as shown above).

Often if your primary gear peanut butters the bike will not roll backwards without a huge amount of resistance. If you can roll the tire backwards with the motor running you will hear grinding and feel the motor skipping through the wheel.

These screws must be locktited and torqued down as hard as you possibly can

The chainring wiggles laterally on the bike but the pedals don’t wiggle

If you pull the crankarms back and forth with perpendicular force to the bike and they don’t move but the chainring does wiggle when you push and pull it perpendicular to the bike then the Phillips screws that hold the freewheel on have loosened up. You will need to remove the axle and then remove these large Phillips screws (they are replaced with the much preferred hex screws on the Bixtrix 100mm drive unit) apply locktite and replace the screws torquing them down as hard as you possibly can without stripping them. I recommend putting the axle in a bench vise and getting a very large Phillips screwdriver and then attaching vise grips to the screwdriver handle and turning them with all your weight on top of the screwdriver. When replacing the axle read the paragraph below on getting the axle tension right.

The chainring wiggles laterally on the bike and the pedals wiggle too

The reason this has happened is because your lock rings at the end of the axle have loosened. This is actually a problem I’ve had more than once and it is a little tricky to fix. There are two lock nuts on the axle that tighten against each other with a rubber washer in between. Almost every drive unit I have ever taken apart the rubber washer is ripped or shredded. It is supposed to keep water from seeping into the drive unit but it gets mangled at the factory and never really works right anyway.

The problem is this. You tighten the first nut down so that the bearings are perfect and have a barely perceptible movement when the axle is shoved back and forth. Then you put on the rubber washer and tighten down the 2nd lock nut against the first lock nut. The problem is that often when you tighten down the 2nd lock nut the 1st lock nut that is already there gets even tighter and then ends up being much too tight. If you can’t turn the axle with your fingers pretty easily when the axle is installed then you need to take BOTH lock nuts off and start all over again. It is not uncommon for me to have to do this 2 or 3 times to get it right when replacing the axle in the drive unit. If it is too tight or too loose you will have problems. Just like Goldilock’s and her bears your bearing tension has to be just right.

The chainring looks warped when the drive unit spins around & chain falls off

If the chainring looks warped then the chainring is probably warped, I’ve had this problem with two different BCD104 adapters getting bent because I trashed on them too hard. Throw them away and buy another one. I’ve also bent the actual alloy chainrings several times too. The best way to see if they are bent is to put them on a totally flat table top and look at them from the side. If they are bent you’ll see it.

If you are having continual chain problems where the chain keeps slipping off the chainwheel no matter how you adjust the tension then you should swap the chainring out to a Raceface Narrow\Wide or a Lekkie Bling-Ring. There are lots of other ways to try to fix this problem, but none work as well as either of these two solutions.

Using a custom removal tool like this one from Cali-ebike makes removal & install of the BBS02 much easier

The motor keeps drooping down like a cow udder when you go off jumps

If you have a 68mm BB BBS02 then most likely the main locking nut on the drive unit has loosened up. Push the drive unit against the frame and use locktite and tighten down the lock nut with a spanner wrench as hard as you possibly can. Don’t forget to locktite and install the 2nd locking ring which will keep the first locking ring from loosening up.

If you have a 100mm drive unit and the unit is loose then the axle extension may have loosened up or stripped the tapped threads and pulled out. This can happen because the tapped threads are just aluminum and the axle extension is steel. The only way to know for sure is to remove the drive unit and check. If the threads on the case have stripped out your only option is to convert that BBS02 drive unit back to 68mm with a 68mm axle and move the existing 100mm axle and axle extension to a new drive unit and re-tap it.

Crankarms don’t line up in a straight line when you look at the bike from the side

This occurs when your axle has twisted or bent. It happens when you are taking your BBS02 off drops, you can try to replace it or you can do what I do and just keep your opposite foot forward on that bike when you ride without pedaling. Most people have a favored foot that they feel most comfortable being forward when you are not pedaling, just swap it with the other foot and keep riding like a hooligan. Either the axle will twist back the other way and be fine or it will break. The crank-arms that ship with the unit are crap as well and I’ve had two of them strip out on the pedal ends. Just throw them away and put on new ones. Make sure you replace it with the right one (R goes on the drive side, L on the non-drive side).

BBS02 throttles can also fail as can the BBS02 displays if you smash them on the pavement, but it is not that common of an occurrence. If you want to be through before you spring for a new controller than you can test your BBS02 will a different display and\or throttle but in all my time reading about failures on the BBS02 I’ve heard of countless controller failures and very few throttle failures (I think only one).

When you get the BBS02 drive unit directly from Bafang, Ebay or many non-reputable Chinese vendors the PAS0 level will give you no throttle at all. I find this incredibly annoying and most reputable BBS02 dealers will sell you a BBS02 that has full throttle at PAS0. Programming the controllers is pretty easy and even non-techies can do it but it voids your warranty so be aware of that before you do it. Instructions for programming your controller are here and the programming guide is here. Be aware that your controller can be fried and you can still hook it up to your computer and access all the settings. When the mosfets fail there is no way to tell it from error codes or the programming interface. If your BBS02 has a Low voltage cutoff that is too high for your particular pack the only way to raise the LVC is to follow the instructions in the programming guide or send it back to your vendor for reprogramming. If you buy a drive unit with a battery pack most reputable vendors will set the LVC on the BBS02 to match the pack it is mated to.

There is a 13 minute video located here of a BBS02 breakdown that shows all the steps for complete disassembly by Guillaume Devot who somehow manages to keep his workbench impossibly clean the entire time. He is most likely an alien from another planet sent to Earth to shame all other ebike builders for their messy work areas.

Ride On.

Well written, concise and all together excellent articles. Seriously, you need to add a donation button to your blog.

Or not.

Either way, don’t stop doing what you’re doing man.

Thanks

LikeLike

Thanks. There is a donation button and some sucker actually sent me $5 once. Still in my paypal account. I’m never going to spend it.

There is no amount of financial reward that can match the stoke I get from people from these articles. I would like to see electric bikes become the dominant form of transportation in America and will do everything I can to that end.

Karl

LikeLiked by 1 person

errer 30 i have put new display and wire harnis still errer30 any ideas,thanks.

LikeLike

Sounds like the only thing left to swap out is the controller. Check for bent pins first.

LikeLike

Pingback: To BBSHD Or Not To BBSHD? That Is The Question | Electric-FatBike.com

Pingback: XT60 & XT90 With Spark Arrestors – Why You Should Make The Switch | Electric-FatBike.com

Excellent article and I read every one.

I have a 750W BBS02 on a bike (Juggernaut Fat Bike – remember – “the only one worth stealing”!) with 7-speed rear derailleur. I haven’t got a lot of Km on it, but a couple of times now I have seen the following behavior

Generally I don’t use the throttle and ride in the city.

However, a couple of times, I have used it, not from a dead stop but when I was going slowly.

I haven’t “leaned on it”, but just a bit of throttle

Essentially, everything dies – power, display, everything

Hitting the power on the C965 does nothing

I get back on the air by removing the battery briefly, replacing it, and powering back up

I am told that my Max Current parameter is set to 25amps and that I may have exceeded that briefly and this is how it would behave. Is that really how it would behave?

I don’t know what the other parameters are set at, but I do have a programming cable, and one of these days I will look at it and perhaps make some changes. I do know it is set for no throttle in PAS 0.

After reading your article, it looks like I am reaching LVC? Not sure what value is set, but guessing 41 or 42. I have an 11.6Ah 13S pack. Would you concur?

LikeLike

I have seen this problem on my Bixtrix 100mm kit which on my Bluto forked bike is my favorite ride. It is insanely fun, but about once out of every 3 or 4 rides it does this, often when the battery is highly charged and always when I am leaning on the throttle very hard. I believe that Bafang added some kind of over amperage cut out to try to protect the mosfets that kills power to everything. It’s not LCV and it’s not a connection problem so that is the only explanation. None of my other BBS02’s do it.

Disconnecting the battery and reconnecting fixes the issue so I have never written about it or mentioned it.

Karl

LikeLike

Thank you Karl. I’ve just been on my second ride after a build – the power cut out whilst using the throttle on a slight hill which sent me frantic. I thought it must be the fuse. Thankfully your wonderful article produced the solution.

LikeLike

Well I dont know what’s wrong with mind I have the eggrider display and the 750c and the eggrider stopped working, hooked up the 750c and had to hold the power button and it gave me the #30 code for the motor. I checked everything on it. Got a used kit that o traded my battery pack for. Hooked up the controller i got with it to my old motor and nothing. Do you think it’s the controller?

LikeLike

my kit from Greenbikekit.com came programmed to run at 24 amps. You could try buying the usb programming cable and set the amps to 24amps, might help.

LikeLike

This is a great article – thank you.

I’ve got a new one for ya. Dropped my bike on the pavement – hard. Still have full display and battery gauge says it’s full. But, now there’s no response from PAS or throttle. I did get the throttle to work once, while lifting the rear end up and seeing if it would work. But this worked only once, and it seemed that the connection was intermittent.

My guess is a solder or something got knocked loose in the controller or BIS, as one of the pedals took the hit and probably sent the shock through the motor/controller. The battery may have hit the ground as well (triangle bag from Luna Cycle), but I don’t think so. I actually ordered a newer controller a while back on sale- so I’m going to swap that out first to see if that does it.

LikeLike

My bet would be an electrical connection somewhere. I’ve seen it where the display works but nothing else does or it immediately shuts off when power is applied. Let me know if it is the controller.

LikeLike

Mine does the same thing! Someone asked to borrow it and they aired it off a flight of 3 stairs. When I turn it on, I still have the full display which reads “99km” (km/hour) for about a second and then switches to display “E.0”, but it also shows my battery percentage. Sometimes if I wiggle the cable to the throttle I can get either full power, or power just to my peddle assist or just to the throttle, but it does not last.

Did the new controller help? I am not sure what to do for mine. An electrician suggested replacing the wire/part that attaches to the throttle.

LikeLiked by 1 person

I am getting a Error Code 30 Communication Abnormality of Controller and Display’ Do you know what causes this to happen and make it unusable? Could you let me know .

LikeLike

Sorry man, no clue. I would check the pins on the display. If that doesn’t work swap the display out (Luna has some dirt cheap ones in their garage section). If that doesn’t work then you’ll have to swap out the controller. Display is a 5 minute job. Controller will take 15 minutes. Get one with the 3077 mosfets.

LikeLike

See also

http://electricbike.com/forum/forum/kits/bafang-mid-drives/troubleshooting-bbshd-and-bbs02/795-error-30-on-bbs01-250w

for a discussion of this topic. (although doesn’t help a lot!)

LikeLike

Hi, I wanted to comment on your last article about new cells but it would have been off topic. I have installed a bbs02 on a bakfiet. The motor is brand new but it acts dead. Everything except the motor works fine. The wires, the battery, the dispaly (when plugged to another bbs02). But it is like the current comes to the motor and then nothing. DIsplay won’t start, motor neither. Any idea what it could be? Thanks.

LikeLike

Sounds like a bad controller. I would double check the connection to the battery and make sure the battery is giving out power then replace the controller. Good luck.

LikeLike

It is double checked. There even is power on the cable going to the controller inside the motor. I hope warranty covers this case.

LikeLike

Thank you so much to publish your article about electric bikes. It is very easier and pollution free vehicle. This article change my thoughts about bikes, now I want to purchase only electric bikes because it is ecofriendly.

LikeLike

Fuck the environment, they are just plain fun.

That being said I do spend a lot of time thinking about the impact of humanity on the earth. One of the biggest contributions you can make is to eat a vegetarian diet as a majority of global warming is actually caused by *drum roll* animal based agriculture.

The other way you can decrease your impact is by buying less shit. That piece in incredibly hard for me (I have 15 ebikes) as I go crazy and impulse shop all the time. I own 6 cars but the last 2 I bought were only $300 so there’s that. I feel like I intercept them on the way to the junkyard and give them a few more years of life with my mechanical magical powers.

Karl

LikeLike

This is the first Mark, from the February 1st comment above (where I dropped the bike and started having issues.) The bike sat for a week, and magically worked for a while. Then Error Code 30 showed up, same issue as Mark #2. I replaced the controller, since I already had one. Not it. Then I replaced the speed sensor. Not it. So, I ordered a new display, which worked out as there was a special offer for the DP14.

The display replacement did the trick, which was confusing since the old display visually was functional. But, it apparently was not communicating well with the controller. Now I have the upgraded controller and the new Lunacycle color display, and spare originals of the BBS02 controller and speed sensor…

LikeLiked by 1 person

Error 30 was from a run of bad displays Bafang sent out. A lot of people got that error too.

LikeLike

Hi Karl,

I had this error 30 on my bike (BBS02). After burning 2 displays i found out that the cable that connects the motor with controller had a short circuit in the junction that splits the cable on the front of the bike. A good working cable has 5v on ground and yellow. Mine had 50v (battery load) on it 😦 Think this happens if you tighten the cable in a bad place so that when you turn you handelbar to mutch there is tension on the junction. Hope this helps. Regards Steven.

LikeLike

Thanks for posting this Steven.

LikeLike

my c965 is showing 30 error i unpluged it all put it back together and now its showing error 04H and when i peddel it works were it didnt work before when showing 30 error i have no control with the c965 just light up showing 04H has anyonelse had these problems ?

LikeLike

Check the cable and the pins for shorts or damage. There was a run of C965’s that were throwing error 30’s. I recommend you try to swap out the display. I really like the new color display, it beats the pants off the C965. Good luck.

LikeLike

Great article, nice to have it all in one place.

I just purchased a 500W BBS02 and started testing it.

I run across the following problem – speed sensor stopped working.

The red light is off and the display (C961) is showing 0,00 km/h.

I noticed it when testing various configurations with programming cable.

Could some settings cause the sensor to stop working?

The motor seems to be ok, both in throttle and PAS mode.

Kris.

LikeLike

Check the connector on the speed sensor. I broke one once and it looked fine but when I took it apart and looked at it carefully it had completely broken the connection.

Every BBSxx unit I’ve seen always has the little red LED lit when the magnet is triggering the hall sensor in the speedo.

LikeLike

I just found the reason…and I feel dummy : )

I had to shorten the chain as it was too loose. That required

moving the wheel a little bit. After that magned and sensor

weren’t aligned any more.

Thanks for your attention, I’m glad it’s just my silly mistake.

It turnes out that the red light is on after contact with

the magned, not automaticaly after the unit is powered.

BTW – I’m just wondering if keeping proper RPM

in BBS02 is so important why don’t we have it measured

and displayed? Or maybe has someone tried it?

Kris.

LikeLike

Hi Karl, do you know the speed sensor wire configuration of the red, black , white wire in the 3 pin plug?

The wires came off the connection inside the plastic casing.

Id like to know if I’m looking at the 3 pin plug with the flat side at the bottom which pin is red ,black , white ?

Kind regards

Tas Papas

LikeLike

Unfortudently I don’t and I’ve had the same thing happen to me. I think that the connector might be keyed. Look at it closely.

LikeLike

Hello

Our BBS02 works fine for one minute or two – then motor stops responding.

Just giving small twitches. Display and battery indicator shows everything is OK.

It seems the battery is giving some power but not what the motor expects.

I can recharge the battery – then next time same behaviour repeats. There are no error messages on display. Battery and motor is <4 months old.

Any ideas or suggestions?

regards

Gaute

LikeLike

I would try it with a different battery and check the battery voltages. When I have had this problem it was the connection between the drive and battery. It could also be a bad battery or a bad controller.

LikeLiked by 1 person

I just hooked up the programming cable to my bbs02. I have never programmed, I just wanted to check the settings that my drive came with. I unhooked my c965 display and followed your instructions on here. When I plugged in the cable from USB port to where the display plugs in there was a spark.

Now the software doesn’t let me read from the motor, when I plug in the display and try to turn it on nothing happens, no display turn on, no motor, nothing.

Any ideas?

LikeLiked by 1 person

Where did you get your programming cable from? The cable is keyed so there should be only one way it can plug in. You may have burned out the controller or with a bad programming cable, its hard to say without touching the unit. I’ve never seen that happen before.

Karl

LikeLiked by 1 person

I got it from Lunacycles, it is keyed. Pretty sure my controller is fried.

LikeLike

If you haven’t already, I would post your issue on the Luna Lounge Forum at http://electricbike.com/forum/. It sure sounds like a bad cable resulting in a fried controller. If you got both from Luna, I have no doubt they will look after you.

LikeLike

Hi,

Did you find out what caused this? The exact same thing happened to me today.. But I measured the cable before trying it, and the P and P+ pins were not shorted. I fixed that before trying it, but did not manage to communicate with the controller. Afterwards I noticed the RX and TX were not crossed and the USB-TTL chip was set to 3v3. I crossed the RX and TX and sat the voltage to 5v, but no success. Now I can’t turn on the bike, nothing happens when I press the power button, other than the red LED on the speedo sensor lights up. Also tried to connect the programming cable to short the P and P+, this turns on the red LED, but nothing happens when I turn the throttle.

LikeLike

Hi there, thanks so much for this informative article. I don’t have the type of unit you are referring to here, but I have a conversion ebike kit that I’ve been using now for two years and have probably put around 2,000 miles on it. I bought it used and it probably had 1,000-2,000 miles on the kit when I bought it. The issue I’m having is the motor shuts off when I’m going up a gentle grade and I’ve tried the tip you gave about disconnecting the battery and then reconnecting it. This gives me power back, but I don’t get very far and it shuts off again. I have felt the motor/hub area and it feels warm, but not too hot where I couldn’t touch it. Once everything cools down am able to ride it again, but within 5-7 minutes of riding it shuts off again. Do you think something inside the motor/hub is damaged or malfunctioning. The kit is a Crystalyte Roadrunner with a Crystalyte CT4825 controller. Any advice would be appreciate and I feel the same as you, I would love to see more ebikes on the road than cars! Thanks

LikeLiked by 1 person

It could be anything. I would check the battery first. It might be hitting the LVC (Low voltage cutoff) if the controller LVC is set too low. Sounds like the power connector to the controller might be bad, or the battery BMS might be tripping. Swap it with another battery and see what happens.

LikeLike

I have a bbsHD and all of a sudden it just blacked out! I am puzzled to say the least! No error codes at all the only way to get it to turn on is to recharge my battery!

also, I do notice that my bike feels like there is too much resistance I am not sure if my battery or BMS…

LikeLiked by 1 person

Try a different battery to find out if it’s the battery or the drive unit.

LikeLiked by 1 person

I’ve dropped my bike a couple times.The first was a hard impack.A week went by and lost all throttle power.The throttle was finely change out when I noticed the thumb lever very loose.

I have the Luna coloured display and the only notice I would get is a momentarily yellow exclamation mark.Having dropped the bike my left hand brake handle need replacing. I’ve looked for information on the bafang brakes, and to see about more information regarding installation.

Thanks take care to ride another day

LikeLike

I got error 04. the store where I bought the bile says it s related to break sensor..

I have no throttle connected (PAS only). the error 04 is intermittent and does not seem to affect the bike. But recently the bike started to run on its own: when waiting at the break light, if I do not hold the brakes, sometimes the motor starts quite violently.. So far it was only when waiting at the stop light, but now the unit continues on it s own time to time even while cycling. This occur no matter which pedal assist level is chosen, even if it is set to 0. I am using a harness made to size from Germany, which has no throttle connector. I am starting to suspect this harness cable might have issues and might be shorting the throttle contacts inside the harness.. But as the issue is intermittent (every few days but more and more often), this is difficult to test. Anyone can advise if I am looking in the right direction? thoughts?

LikeLike

Hi, thanks for this really helpful article.

Just one question. I connected a new display on my bafang wiring harness. Unfortunately during this operation I put my screwdriver în the green connector and I touched several pins at the same time (with battery plugged). I created a shortcut and generated a spark. Now the display doesn’t start any longer…

What can be damaged? Is there a fuse on the controller that can be changed? Shall I change the whole controller?

LikeLike

Yes, it’s a 5 minute job.

LikeLike

Shall I unmount the motor from the bike or can I do it with the motor installed?

LikeLike

Sorry if you already received this from me.

Thanks for rhe article. I gave a 750W bufang motor. It just started an issue. When I stop pedaling the motor does not disengage.

All else is good.

LikeLiked by 1 person

I’ve not seen that behavior. If the pedals keep turning then one of the chainring bolts is hitting the crankarm. If the pedals are not turning but you can hear the motor turning it might be a problem with the drive unit or the programming. The default programming keeps the motor running for a few seconds after you stop pedalling which I think is too long. Try lowering the TIME OF STOP variable under the PAS screen.

LikeLike

Have u managed to fix this? I have the same problem

LikeLike

my bafang c695 has error code 30

LikeLiked by 1 person

Hi Karl, great article. 🙂

Can you give me some pointers with my BBS02, it has been working fine until a couple of days back. The battery was about 3/4 charged and I rode about 1/2 mile on the flat so the motor was fairly cool. I stopped for a couple of minutes, when I got back on to the bike I noticed that the screen had shut down (quicker than was usual). So I pressed the centre button to start it back up, but it was totally dead.

I have charged the battery to full and it seems to be fine with 53v when checked with the test meter, the voltage doesn’t drop when trying to boot it back up so I assume it’s not a lack of capacity.

I have looked over all the wiring and can’t see a loose/ damaged connector or wire.

What should be the next logical step to check?

LikeLike

Hmmm, I had that problem with the color display. Turns out you have to press and hold the button for a few seconds. Not sure why.

Other than that I have no clue. Get a cheap watt meter for $16.50 and that will tell you if it’s the battery of the drive unit.

https://electricbike-blog.com/2015/02/11/16-50-fuel-gaugetroubleshooterwatt-meter-for-your-electric-fatbike/

Karl

LikeLike

Thanks Karl, I’ll look into it further and let you know how we get on.

David

LikeLike

I took a close look at the the display this morning and with a voltmeter I can detect the battery voltage up to the inline plug immediately before the display unit, the display won’t work even when holding down the On button for a full minute, so I assume the display has had an untimely death. Strange, as it had only been running for a short time on a warmish day (about 20C), no rain and under no strain at the time.

LikeLike

I have managed to purchase a DPC14 colour display locally and when plugged in it gives an ‘Error Code 30 Communication Error’, so I assume the controller is dead. The mosfets seem OK when doing the test with the multimeter that you show on your page for testing them. I’ve removed all the potting and can’t see (or smell) any obvious fault, I’m guessing one of the memory chips has failed?

LikeLike

SOS

hello, recently I purchased a bike with the BBS02 750W motor -version B. Absolutely love it, ebikes have got me hook line and sinker. Three months after I purchased it, I started to have problems. The symptoms are complete loss of power, for no real reason. Will happen on any PAS level. When I disengage , then reengage the battery it will power back up, but then the same thing will happen again.

Can anyone Help ?

LikeLiked by 1 person

I think is that the motor nedes to much batery

Just look at the display on the WATTS used for every internel gear

LikeLike

controller is dead

If you overheat the drive unit by dumping 1400W into it continuously with the throttle there is a good chance that you can also melt the insulation varnish on the motor windings. Melted motor windings can lead to a motor that doesn’t power up at all and acts nearly identically to burned out mosfets on the controller. If your motor stops working and it has been under load the first thing you should do is put your nose right next to the unit and take a good long sniff. If the windings have burned out usually you can smell it for a short period of time after they fry. In contrast burned out mosfets will not smell at all. The easiest way to check to see if the windings are melted is to take the motor apart and do a visual inspection of the windings. If the windings are melted you should see black marks where the motor overheated and the varnish melted.

maistudodigial@Gmail.com

LikeLike

controller is dead

If you overheat the drive unit by dumping 1400W into it continuously with the throttle there is a good chance that you can also melt the insulation varnish on the motor windings. Melted motor windings can lead to a motor that doesn’t power up at all and acts nearly identically to burned out mosfets on the controller. If your motor stops working and it has been under load the first thing you should do is put your nose right next to the unit and take a good long sniff. If the windings have burned out usually you can smell it for a short period of time after they fry. In contrast burned out mosfets will not smell at all. The easiest way to check to see if the windings are melted is to take the motor apart and do a visual inspection of the windings. If the windings are melted you should see black marks where the motor overheated and the varnish melted.

LikeLike

I connected the battery wires to the wrong motor I connected the black wire to the red wire and now my motor does not work will it have some protection fuse that may have burned that I can change?

LikeLiked by 1 person

I finally got around to installing my bafang 750w . I tested it before making final connections and all was good . I disconnected the battery and when I was trying to put a quick connector on the motor power leads they touch off each other and sparked , I assume there is an internal capacitor(s) with stored energy as the battery was disconnected.now the motor won’t run so does anyone know if there is an internal fuse or am I facing another hefty bill for a new motor 😩

LikeLike

I just bought a BBS02 750W with a 48 volt 11Ah battery. I installed the motor kit on a Walmart GMC Denali road bicycle and I have it configured for 9 pedal assist levels. When I put the bike in high gear (hard to pedal) and in pedal assist 7, 8 or 9, and start out from a stop, the motor will cut out for a a split second than come back on. It does this over and over again until I get going. I can feel it happening the least in pedal assist 7, and it happens a little more in pedal assist 8, and its worse in pedal assist 9. If I am in a low gear it doesn’t happen and it doesn’t happen when I use the throttle. It seems to happen when I put the most load on the motor in pedal assist mode, which would be when the bike in the higher gears using the higher pedal assist levels. Any ideas? Thanks!

LikeLiked by 1 person

My guess is the programming. Try Karl’s special sauce.

LikeLike

i have the 48 v 16 ah batery and it makes troubles to, probebly a batery 48v 25 ah will work on any assist level

LikeLike

Hi Karl, thanks for the troubleshooting guide. I still have an issue not listed here if you can help point me in the right direction I’d be most grateful.

Power cuts out within a second of being applied in all PAS levels and also when using the throttle.

All wiring connectors checked and double checked and my battery stays connected and LCD screen power does not falter either. I can see voltage happily not going below 48v and this 11.6ah pack has previously done close to 100 miles and has shown itself to perform very well.

So I have no error codes and no strange voltage sag, no LCD or cable issues but still it cuts out.

Anything sensible to check because i’m at a loss where to start with this particular error and not able to find someone else with the same issue as yet.

Cheers

LikeLike

When I have had this issue it has been the connector between the drive unit and the battery. I would try that first, then try another battery then try swapping out the controller & then dinally the display. If none of those things fix it then it is probably a short inside the drive unit itself. I have one BBS02 that has intermittant power issues and I’ve tried everything and it still happens. Luna sells the bare BBS02 for pretty cheap if you need just a new drive unit.

LikeLike

Thank you for the guidance. A logical path to follow was much needed

I have no more XT90 so tried it with an XT60 to no change.

Re soldered the XT90 back, again no change.

After this I tried with each brake sensor cable removed and started working through each connector left.

If I unplug my gear sensor cable, my throttle works as before and the bike sustains power without issue.

The sensor is the type that the gear cable goes directly through to detect shifts and is mounted on the underside on my crossbar near the front.

My questions are, would you replace this before moving onto the LCD or controller inside the motor itself?

Is it safe to ride providing I simply only chnage gear while not pedalling of using the throttle?

Are these type of gear sensors prone to damage or moisture and is another type perhaps a better choice to replace it with? Or just mount a new one with some kind of protection? Is there a better place to mount it you can advise?

Massive thanks Karl, I doubt i’d have even got this beasty rolling at all without your guidance.

LikeLike

Just get a replacement gear sensor then. It sounds like there is an issue with the one you have. The display is probably fine.

The only connectors I’ve ever had fail was the Andersons, the XT’s always seem to work.

LikeLiked by 1 person

Hey boss, goldmine of a site, many thanks.

Enjoyed the electric Burn article! If I’m playa bound again it’ll be an electric boogie.

So I mounted a recumbent seat on a Larry vs Harry for my adult son coupled w the 750w.

PAS just went south? Throttle, shift sensor work fine. Disconnected battery and other leads but still dead.

LikeLiked by 1 person

Try several different PAS levels. If you didn’t mess with the programming then I would check the grey wire that is in the 4 conductor plug to the controller. If that one has a bad connection then PAS won’t work. Other than swapping out the controller there isn’t much you can do (assuming it’s not a damaged grey wire).

LikeLike

Thanks for the getback, I noticed you pointing out the grey psa wire on the temp sensor install.

I’ll take a peek.

LikeLike

man, no cure for stupid at times.

re-disconnected everything before I opened her up and psa kicked in. One of the brake magnets migrated.

I guess the throttle works fine even if the brake leads are hooked up but the magnetic sensor is off?

Or is it all just a blur?

Many thanks, keep on rolling

LikeLike

Tons of info about the BBS02, gave me a few hours of reading the computer screen.

Thanks for your effort Karl ! This site made me confident to buy a 500W-48V Bafang and built it onto my wife’s KOGA hand built “signature” bike.

LikeLike

I bought a secondhand bike before the winter with a BBS01 250w motor and C965 display, which now after being stored in my garage over the winter suddenly shows a error 30. Everything works well enough and I can ride the bike, but its frustrating having the error show up. From what I have read I understand it might be the display or controller. If I were to change/upgrade my C965 display, do you have a recommendation for one that fits well and is a better upgrade??

Thank you so much for all the info I’ve got here, and thanks in advance for any help!

LikeLike

I’m quite certain that error is the display or the cabling.

LikeLike

I bought a used Specialized Stumpjumper mtn ebike with Bafang BBS02, it goes about 35mph with full throttle and pedaling hard, love it. It worked fine for many months, then occasionally the PAS would keep assisting even when I stop pedaling (very dangerous) and I had to turn down the PAS level to 1-2 to get it to stop. Now this happens 95% of the time and recently I get error code 21H, thumb throttle not responding and speedometer shows 0mph, all issues at once. I noticed the speed sensor red LED no longer lights, I replaced it with same result. I suspect there is an issue with the controller inside my Bafang motor. Wiring on the bike looks untouched and ziptied securely. Any suggestions?

LikeLike

I agree, it sounds like the controller. Check the speedo wiring harness to make sure there is no damage. There is 2 different controllers Rev A and B, make sure you get the right one. About $60.

LikeLike

Thank you Karl. Do I need to open my Bafang motor to look if I have Rev A or B? I prefer not to open until I replace the controller since I can still use the bike until then…but I will if required. Since this bike was “hot rodded” to go fast, do I need to program the new controller and buy the USB dongle to do this? I appreciate the guidance for this newbie.

LikeLike

Check out this article. https://electricbike-blog.com/2016/07/12/bafang-completely-redesigns-the-bbs02-and-tells-no-one/ You can also get a programming cable and copy settings to the new controller. It’s pretty easy, to do. Check out this article. https://electricbike-blog.com/2015/03/17/programming-the-bbs02-without-frying-your-controller-and-losing-your-sanity/

LikeLike

Hi tell me. I bought a new set of Bafang BBSHD mid drive 48 in 1000 W and when the throttle stick is connected, the display gives error 30. If there is no error in disconnecting the throttle stick, the engine runs on the assistant. What could be the problem ? In the gas knob or in the controller too?

LikeLike

I have a really loud whining sound after only 300 miles on a bbs02 Juggernaut Classic from Biktrix. Link to video:

LikeLike

Yeah that whining is loud. I’d try to grease the secondary reduction. I’ve not heard anything that loud.

LikeLike

Thank you Karl! I will try greasing the secondary.

LikeLike

Hi Karl, the bottom of my Bafang has a white label showing: Middle Motor BBS02B DC 48V. I also bought the bike in mid 2017 and seller claims he had just built it so I assume it’s version B I need? I don’t want to take it apart and loosen the ziptied cables until I am ready to replace the controller as I still use the bike in its dysfunctional state (gently). Thank you for the links and programming info, looks like I’m going to learn how to fix and rebuild ebikes soon! Anyone near Santa Monica?

LikeLike

I greased the nylon gear and I am still getting the same loud whining sound. Do you know what else this could possibly be? Maybe the controller? It only gets loud after riding for a few miles at higher speeds.

LikeLike

I’ve got a stumper here. BBS01 built to use a 36v battery, at some point decides to accelerate when power is applied (throttle = MAX, pedal = MAX), but brake cutoffs work fine, back pedaling works fine to stop the motor. Fast forward past frustration, purchase BBS02 controler to replace BBS01 controller, bringing it up to 750w and “48v”, so I strap my 52v battery to it, and same issue. All throttle, all the time (except when at an idle or when brakes are on or back pedaling). Throttle is the issue, you say? I unplug the throttle completely, same issue of max throttle. Controller issue you say, but same controller issue on original BBS01 and new BBS02 controller on same bike? Could it be wiring? Could it be that the display is wonky and not communicating with the rest of the Bafang? Suggestions welcomed. I can’t seem to find anyone who’s had this specific issue. I’ve read others saying that “If you are at full throttle, then you MUST have a broken throttle!”, but what if you have no physical throttle?

LikeLike

My money would be on a shorted out wiring harness. That is a weird issue. If the hall sensor wire was shorted in the cable and was reading 4V+ all the time that would cause this issue.

LikeLike

Can someone PLEASE tell me why the battery icon on my c695 is flashing empty and showng no bars with fully charged battery on a newly installed bbs02 that won’t work? This is fresh out of the box.

LikeLike

Did you figure it out Doran? I’m wondering the same thing on mine, but mine works. It flashes first few seconds of startup as empty but then works fine (showing full battery). Yours too?

LikeLike

Hi Karl, just wanted to update, after I got the new controller the PAS is working normally again, it stops when I stop pedaling. My thumb throttle also went out so I replaced it and works fine. Speedometer wasn’t working since the magnet got moved on the wheel. I ordered the programming cable to copy the settings from my old controller to the new one to get the higher speeds again. I appreciate the support here, it’s such a new world and not easy to find people who know this stuff or shops who want to touch it. I had Bike Attack in Santa Monica install the new controller as I don’t have all the tools or experience to do it myself. Owning/Repairing ebikes can be quite costly but still well worth it.

LikeLike

Blown my battery and motor by plugging in a shorted display. I plugged in the display and saw smoke from the middle of the frame. unplug display. more smoke from the battery tied to the crossbar in a football boot bag. unplugg from motor. put in garden and flame, co2 extinguisher calmed it down. The bbso2B battery connections now measure 1.8 ohms either way. Ive pulled all the potting out , but the regulator is on the underside i believe. hot air gun tomorrow.

LikeLike

Hello, thanks for the article. This was really helpful. I have usually the phillips screws that hold the freewheel on have loosened up… That’s second time I have the issue.

Maybe I’m not strong enough to tighten them. I would like to replace with hex head like proposed in article, but I forgot to take the dimensions last time I opened motor. Do someone has the info? It seems to be around M4 or M5 and around 8-10mm length?

Thanks for your help.

LikeLike

I would pull them and go to the hardware store to get exact replacements. My experience is that Ace\True Value has the best selection of individual screws

LikeLike

Hey. I thought I posted here before, but don’t see my post, so sorry if this is a repeat. My question is regarding my speedo not functioning. The red light won’t come on and it appears that it’s not getting 5 volts from the controller. So now what? 1) Get a new controller? 2) Get a reed switch sensor that shouldn’t need the 5 V ( I read about this somewhere), or just forget about it and 3) get a stand alone speedo so I can see speed and distance etc?

Curious if not having it hooked in affects the behavior of the motor? Pedal assist seems to work fine, but this is my first bike, so I don’t really know what it should do.. Thanks so much in advance. Gabe

LikeLike

Check the pins on the speedo and the cable to make sure it didn’t get pinched too hard by a zip tie. The speedo is cheaper to swap out, so I’d do that first, then the controller.

LikeLike

Right.. yeah, I already swapped out the speedo with no luck and I don’t see any kinks or pinches in the cable. I’ll open up the controller and look for a bad connection there next. But.. what about the question of performance/behavior of the motor? Does the speedo not being connected affect how the controller/motor operate? Thanks so much for spending ANY of your time answering my questions. Gabe

LikeLike

When I replaced my non working thumb throttle, the speedo started working again. Just a thought.

LikeLike

Thanks Aje.. yeah, my thumb throttle works fine along with everything else as far as I know.

LikeLike

I’m not sure, I’ve never had issues with the speedo affecting any functionality except with some displays if there is an error 21 you can’t set the PAS level. I’ve had several people with damaged speedo wires have very strange things happen.

LikeLike

OK.. Yeah, seems to be working OK. I guess I’ll take the easy way out now and just get a stand alone spedometer so I can track distance and speed. Thanks again.

LikeLike

Hi Karl, my rear hub Bafang motor died going up a hill one night. I was able to cycle home manually without motor assistance but the front light kept flashing on and off, the speedometer showed random speeds and error message 08 appeared for a few moments. Mechanically, the bike pedals normally but no electric assistance, not even a noise or vibration from the motor. However when I roll the rear wheel backwards, the hub sticks a bit and does not spin smoothly and there is a lot of resistance. What do you reckon? Is the problem in the Controller or in the Motor?

LikeLike

It sounds like you messed up the reduction gears. With most Bafang hubs you can buy an identical hub then swap the main unit out while leaving the stator laced up with your original wheelset. This will keep you from having to relace a wheel which is a royal PITA.

If you can find someone that sells the reduction gears for that motor you can get the reduction gears and just swap those out. It will be cheaper.

Talk to the ebike manufacturer.

LikeLike

Thanks very much for your reply. The bike manufacturer offered to send me a complete new wheel with motor, gears and brakes so I can fit it easily. However I’m worried there’s an electrical problem because there is no life whatsoever from the motor and surely a broken reduction gear would make some noise?

LikeLike

My Bafang mid drive does everything well for many miles. I love it All I have ever done is change the display and throttle. Now it wants to run full speed in PAS or throttle. Come off the throttle and it behaves normal. All levels the same. I still use it but on some trails it is dangerous. Any suggestions?

LikeLike

I had the same issue, PAS wouldn’t stop but I had to lower PAS to 0 to get it to stop, very annoying. Had to change the controller, ordered new one from Luna around $110 plus $80 for Bike attack to install. My original controller was “overclocked” to go up to 1500W. I thought the new Luna driver would also be that strong but it cuts out around 1000W so my max speed is around 28 vs. 36mph with the older driver. I suspect my hard riding on the throttle with 1500W overheated my original controller, and resulted in the PAS issue. This is one thing I dislike about the Bafang mid drive system however I can’t blame fault on it failing under normal use as I bought mine modified and not much warning or explanation to go easy and watch how hot the motor gets. Now I’m much more careful and conservative too. This can’t really happen on my other factory built ebikes but they have other issues I’ve dealt with, some worse.

LikeLike

HI, just a quick question for,troubleshooting. Is the brake cut off controlled by the controller or the display? I have an eggrider that is not communicating with the controller and am trYing to troubleshoot if the display or the controller is at fault. The engine will work when pedalling however the brake cut of will not turn the engine off.

LikeLike

I’m 90% sure its the controller.

LikeLike

My Bafang motor has started making a clicking sound but only when pedaling with PAS. Initially it was only at the down stroke on the pedal but now through the entire cycle. The sound is not there if using the throttle. Any ideas of the cause?

LikeLike

Hello Karl,

Thank you for this article which is of a great help for everybody.

I hope you are well although what’s happening currently to all of us…

II have got a Bafang BBS01B since 8 months. Everything was working fine until today.

Since the Covid I put the bike in the garage and did not touch it for few weeks.

Last day, I tried to power on, but nothing was showned on the display, nothing happened.

After some minutes and many retries, the display is lighted on and everything things seems to work well and motor too. So I was a bit worried…

I retried it today, same issue, I could see the display showing stuff for few seconds then black screen, and then nothing more. No way to get the display and engine power on…

I checked the battery which is fine and fully charged.

I checked voltage with a multimeter before motor power connection, I properly have 36V from the battery.

I check voltage of output motor and I have a small 0.2V remaining, I don’t know what is and if this is important, maybe related to some condensator stored micro currents ?..

I opened the controller and did not saw anything relevant, connections seems fine, no water or dust.

It’s like it just does not work anymore for now apparent reason.

It was working properly, just the fact leaving the bike alone for some weeks seemed to be enough :-s

Do you have any clue for this ? Should I replace the controller ? What is the proba it comes from there ? I currently have a 36V 250W BBS01B, can I replace with a more powerful/robust controller by the way ? A BBS01 500W ? or BBS02 ?

Thanks for your help

LikeLike

I have seen this a lot with the connector between the battery and the controller fails. Pull it apart and check and replace if needed. Sometimes I solder the wires to make sure they have a good connection. The Anderson PP connectors do tend to fail sometimes.

LikeLike

Thank you for your answer.

Do you mean that voltage can be good even with if there is bad connector to reach the battery ?

According to you this could be enough to not deliver proper power to the motor ?

LikeLike

Another question:

Can it be related to the battery itself or the BMS not working properly ?

I get a valid voltage but maybe the current is not delivered at all…

Have you already seen a controller receiving enough power but not giving any sign of life like mine ?

LikeLike

Maybe my explanation were not clear enough : I measured the voltage received by the motor, so at the closest possible position to the motor, without any connector between my measure point and the motor. I have also tried the mosfets test of my controller : https://www.ebikes.ca/documents/BlownMosfets.pdf. Everything seems normal according to this test…

LikeLike

Yes, I’ve seen it where the display shows up but the motor makes no power and when there is nothing sometimes it cuts out intermittently. Most problems end up being that connector.

LikeLike

Ok I will check the connection with the battery and make sure everything is fine on that side. I will keep you informed. Thank you!

LikeLike

I did a connection between the battery & motor by myself using this method : https://www.aliexpress.com/item/32910588091.html?spm=a2g0s.9042311.0.0.5f646c37HsrQc0

I have found my connection was really bad : when using heat to shrink the connector, this burnt the connector too much, positive & negative wires were almost into contact :-s

I not proud at all, and will do something much better this time.

Thank you again, you are a genious.

LikeLike

Hello

Please can you help me? I am really confused! My BBS02 pedaling is shit! Please watch the video and try to understand what is going on! PLEASE

https://drive.google.com/drive/folders/1gqvb_eDRITrOKZJxmWF5GKFAhUGFl8xP?usp=sharing

https://drive.google.com/file/d/14dPRp7cNPxrz1yxDhNpF7BdkexE2Wre9/view?usp=sharing

LikeLike